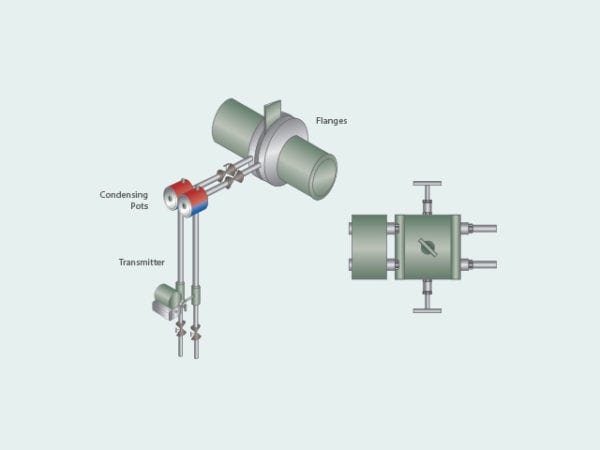

The basic concept of impulse tubing for steam flow instruments is the same as that behind impulse tubing for liquid flow instruments. However, additional problems are introduced in

Receive the latest news and offers

Get it sent to your email address!

The PDF document will be sent to the email address specified.

By submitting this form, you consent to receiving marketing communications from Inveno Engineering. We never spam, only valuable information here!