My name is Kelly Paffel, I'm technical manager for Inveno Engineering, LLC, located in Tampa, Florida. Our firm is focused on steam and condensate systems. And today I want to talk about Steam Trap Station Testing Methods.

To manufacture products of the highest quality, you need steam systems that offer unparalleled performance and reliability.

The steam and condensate experts at Inveno Engineering LLC have one goal: helping your plant achieve a world-class operation. Inveno can review your entire steam and condensate system from generation to distribution, from end-user processes to condensate recovery.

We are so confident our solutions will exceed your expectations that we offer a 100% satisfaction guarantee.

Whether you’re expanding your steam system or building a new facility, partnering with Inveno ensures your steam system is designed properly from the start. We learn your objectives, study your operations to identify and resolve problems, develop a road map to achieve your goals, and walk you through the proposed modifications.

My name is Kelly Paffel, I'm technical manager for Inveno Engineering, LLC, located in Tampa, Florida. Our firm is focused on steam and condensate systems. And today I want to talk about Steam Trap Station Testing Methods.

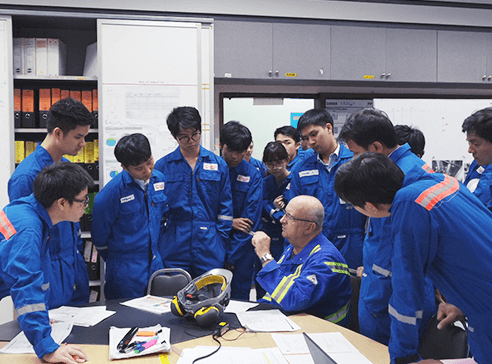

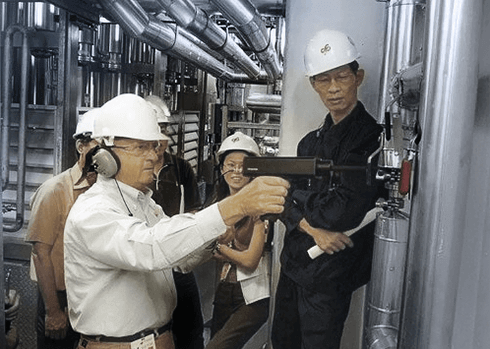

Inveno Engineering LLC provides Steam System Engineering Training classes designed to deliver field experience and practical knowledge to plant engineer/management personnel who work with steam systems. Our lead instructor has more than 35 years of experience in all aspects of steam systems and commands a wealth of knowledge. His detailed instruction gives attendees the in-depth knowledge they need to succeed on the job.

We are steam system solution providers: our sole focus is solving our clients’ steam system issues. With every client engagement, our objective is to optimize the safety, reliability, energy usage, and overall performance of steam systems.

Inveno Engineering has a deep roster of internationally recognized experts in steam systems. Our team members apply their vast years of experience and expertise in steam system technologies when they review entire systems, so they can outline a methodical, detailed road map for improving their performance. Our innovative, thorough solutions help our clients eliminate premature failures and provide greater reliability, saving them time, resources, and money.

Although our list of clients and success stories is vast, the true measurement of our capabilities is client satisfaction, and we offer a 100% satisfaction guarantee. Our commitment is to do more than meet our customers’ expectations: we pledge to exceed them.

Receive the latest news and offers

Get it sent to your email address!

The PDF document will be sent to the email address specified.

By submitting this form, you consent to receiving marketing communications from Inveno Engineering. We never spam, only valuable information here!