Sizing A Steam Trap

My name is Kelly Paffel, technical manager for Inveno Engineering, LLC. We’re a domestic and international engineering firm, specifically in steam and condensate systems. Today I want to talk about steam trap sizing, just an overview of the critical factors and sizing a steam trap properly.

Understanding steam trap sizing, important factors. Yeah, we need efficient, reliable steam trap operation, and that is proper sizing. Correct operation. The design of the steam trap is selected, sized, and installed perfectly. Incorrect steam trap sizing will cause either condensate backup or steam loss. So one of the main failures of steam traps is improper sizing of the steam trap.

Steam trap sizing does that mean sizing the steam trap by connection size. 3/4″ connection doesn’t mean a 3/4″ steam trap. It’s sizing the internal orifice of the steam trap, and that’s what I want to talk about today.

What is needed for proper sizing? Of course, understanding the condensate capacity, what is the condensate capacity of the system? And there are calculations that we have to do to come up with the correct capacity. P1, understanding the inlet pressure. P2, understanding the outlet pressure. Probably P2 is the biggest factor in determining the steam trap sizing because P2 is normally not known in the system.

Connection size to meet the installation requirement. So if I have a process outlet connection of 1″, I’m going to put in a 1″ steam trap, I want unrestricted flow to the steam trap. Remember one thing, condensate gets to the steam trap by gravity, not by pressure or velocity.

Understanding the pressure and temperature requirements. Data, What is the information necessary to size a steam trap? Of course the maximum pressure on the steam line supplying the process. The thing is, is that the steam trap orifice has to be rated for the highest pressure. So the operating pressure is a hundred PSI, but the safety valve is set for 150 PSI, then the orifice maximum pressure has to be rated for 150 PSI.

Maximum temperature. Again, we need maximum pressure and temperature for the body rating of the steam trap. So 150 PSI is 366 degrees, so the steam trap has to be rated for 150 PSI, 366 degrees.

Selection of the steam trap orifice. Again, we talked about the maximum steam pressure rating, the maximum pressure rate is determined by the safety valve.

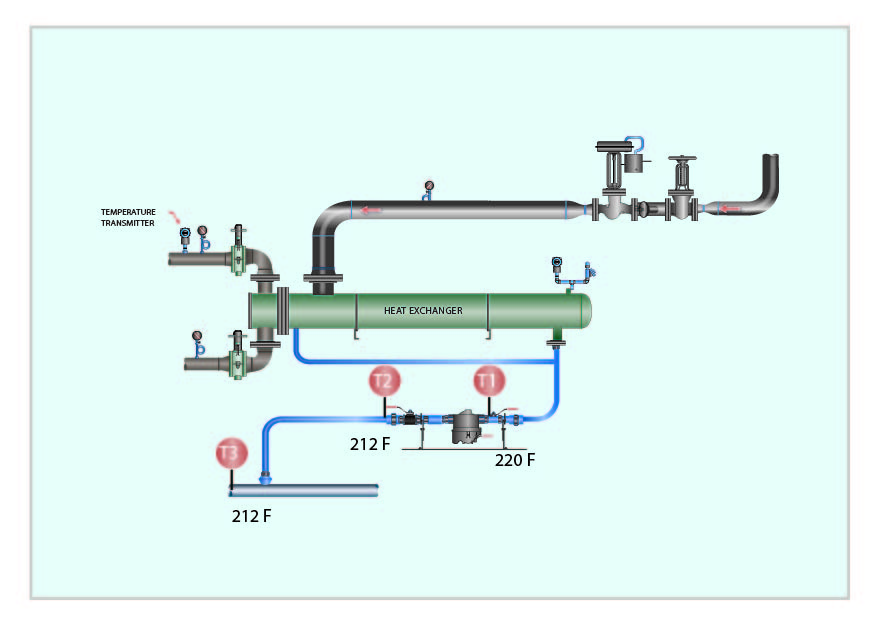

Here are six points that we need to know, six pressures. And the thing is when we’re sizing a steam trap we need to know P1, and typically we will know that the operating pressure is 75 PSI. Well, there’s going to be a pressure drop across this control valve so we need to know P2 the outlet of the control valve. 75 PSI in a control valve doesn’t mean we’re going to have 75 PSI at the outlet of the control valve. We’re going to be let’s say 15 PSI pressure drop through the control valve.

And when we go through heat transfer there’s going to be a pressure drop, and that is given to us by the heat transfer manufacturers. Now if we say it’s 10 PSI pressure drop through the heat transfer here or P3, so I take 10 from 60 PSI and I come up with 50 PSI at P4 inlet to the steam trap. Remember I said we need to know the inlet pressure to the steam trap, so that would be P4.

Then the outlet pressure of the steam trap is P5. And we need to know the condensate line pressure P6. The thing about P6 and P5 that’s usually not known, people do not install pressure gauges on the condensate system which is really critical because sizing the steam trap is a differential pressure across an orifice. A steam trap is nothing but an orifice, and we need to know the differential pressure across that orifice, plus the capacity to come up with the correct sizing. Therefore in your system you should know what the condensate line pressure, either install pressure gauges there in the system, but understanding the pressure in the condensate system.

So just to go through what we already talked about, determine the inlet pressure to the control valve, document it, determine the outlet pressure of the control valve, which we talked about was 15 PSI pressure drop, and pressure drop in the heat exchangers. What is this given by this? Heat transfer manufacturers will tell you what the pressure drop.

And then we come back to our example. Again, P1 to the system, let’s say the safety valve up here is set for 150 PSI, so the pressure body rating of the steam trap and temperature would be 150 PSI, 366 degrees pressure drop across the valve, pressure drop through the heat exchanger, we come up with 50 PSI here at the inlet, and let’s say our condensate system is a gravity system which is operating at zero PSIG, which is seldom ever found, but for this example we’ll say it’s zero PSI. So we would size a steam trap for 50 PSI differential across that steam trap with the capacity.

So just to go back through what we just seen on the example, calculate the end pressure to the steam trap, let me set 50 PSI, determine the outlet pressure of the steam trap. We have a pressure gauge on the condensate system, zero PSI. It’s a gravity system and calculate the condensate flow in pounds per hour. So this is part one of steam traps sizing, and I will go through in part two capacity charts, a couple of the basic calculations, how to come up with the sizing of the steam trap and a couple of examples of it, but this is part one.

Now on this presentation, if you come to our website which is www.invenoeng.com, we’ll have a best practice number 67 which is a document we’ll go through all of these different things that I’ve been talking about on steam traps sizing, so please visit our website. Now there’s 67 best practices up there besides this video will be posted up there. Also, the other thing is, is that we’re here to help you support you in engineering in the system long-term, short-term impacts on your system, engineering assessment, balance reliability, training of course is very important, and project management.

And here is my contact information, at any time you have questions regarding steam or condensate, please email me, I’d be more than happy to assist you, and I’m available all the time by email, and typically I will answer emails in 24 hours or less, so please contact me. Have a great day.