Why Standard Operating Procedures are required for Steam Trap Station Testing

Maureen: I want to welcome everybody to our first Steam Timber webinar for 2017. I think this is our third September now where we’ve kind of decided to shift our focus and kind of devote the whole month in all of our webinars, and a newsletter information, and so forth to everything to do with steam. So, we appreciate you having an interest in that and being with us. We’re also happy to have Kelly Paffel with us, who’s going to be talking through why standard operating procedures are necessary for steam trap inspections. So, it’s always good to hear from Kelly and he’s always got great information. So we’re looking forward to what he has to say here in just a couple moments. So just a little bit of housekeeping before I turn things over to Kelly, I am recording this. So, if you have to hop off early or you’ve got colleagues who you want to have listen to this information, we will have that available up on our website. Most likely later this afternoon, I’ll be able to pop that up there. So, you’ll be able to check that out.

Maureen: Also, we do have the ability for you to ask questions. There’s a little questions box. You can type in any questions you might have throughout the webinar and I’ll get those over to Kelly throughout the session and then, of course, at the end, we’ll have time for Q&A as well. So, definitely take advantage of that. Again, as you saw from the beginning, if we do have any technical issues throughout, we’ll try and get them fixed as quick as we can. That’s just part of doing these things live, but we think there’s value in it. So, that’s how we’re going to keep doing them. So, anyhow, with that, I am going to turn the screen over to Kelly. Kelly, welcome and we’ll let you take it away.

Kelly Paffel: Very good, thank you. My name, again, is Kelly Paffel. I’m Technical Manager for Inveno Engineering LLC. We’re located in Tampa, Florida. Today, I’m going to be talking about why is it necessary to have a standard operating procedure or what’s abbreviated, it’s called SOP for steam trap station Testing and Assessment. There’s a question comes up is why we have a standard operating procedure. What is a procedure? So set forth the requirements necessary to safely and successfully complete a steam trap station assessment at the plant. So, the procedure is that we can have people go out and conduct a steam trap testing assessment and have it repeat to be accurate every time. Without an SOP, how do we know each test will be done correctly? Do we just assumed the person knows what they’re doing? Do we assume the person is doing the procedure correctly? The thing is, is that we counter-assume then we will not get repeatability. So that’s the reason for an SOP.

Kelly Paffel: The other big advantage for having an SOP is how do we train people in the future for doing a testing, how do we pass down this knowledge. Once SOP is developed, it’s always a continuing developing document, meaning, that the person that’s in control of the document or people are continuing to add to it or improve it. So, the thing with having new people come on, they’ll have a document to file to make sure that they’re doing the test correctly and repeating each test. Example would be when I go into an airplane, the pilot’s been there for 25 years flying the airplane. If you look in the cockpit when you’re getting on the airplane, what’s he doing? He’s going down his checklist or his SOP to make sure that he can get the plane up in the air safely. So SOP is used in all types of industry to make sure that the product is produced repeatedly, and accurately, and a quality standard is maintained. It’s the same thing when we’re doing steam trap testing.

Kelly Paffel: The other thing for plant operations, if I’m going to hire an outside firm, how do I evaluate the outside firm that’s doing the steam trap assessment? Do I evaluate them just because they have an ultrasonic unit or a temperature measurement, that they’ve been doing it for 10 years? The thing is, is that when I evaluate, people coming on site to do work for me on testing, be in non-destructive. I’m looking at their qualifications but I’m also looking for their SOP or their procedure documents. If I look at a company’s SOP for steam trap assessment or testing and it’s two paragraphs that tells me one thing. If I look at their SOP and it’s 56 pages long and then that tells me something else. So, the thing is, is that which company do you hire, the one that has two paragraphs and one has a document of 56 pages? The thing is, is that the SOP that we follow with our staff is 56 pages in length. So we go through everything to make sure that our staff members are doing the testing correctly and repeatable.

Kelly Paffel: So the SOP will provide indication on how the company will check their staff performance. As I go out, and supervising, and managing a steam trap assessment, I can go and check their qualifications or quality control check so I see how they’re performing per the SOP. So it provides a lot of different value aspects. One of the things that SOP goes through is when you’re going to do a steam trap assessment, who gets involved because everyone gets involved, the plant management, purchasing, engineering, maintenance, and operation. Everyone needs to be involved. Just having one person involved is not good enough. So the thing is, is that everyone needs to be involved and that’s part of the SOP is who do I communicate to, that this is going to occur, who needs to be involved or everyone, the plant management, purchasing, engineering, maintenance, and operation.

Kelly Paffel: Some of the other things that need to be included into the SOP is defined the team, field members, who’s going to be doing this, do I send one personnel. Sending one personnel, it’s very difficult to do any steam trap assessment with one person. So we set up what we call the team which is the testing person. That testing person is using ultrasound, and infrared, and tagging, and locating, and another person for data collection. The thing is, is that to go on just testing without collecting data, it’s not going to be a successful assessment. So, we’re looking at a combination of people. And then there’s also support people, the support people or possibly the people that are putting the information into the software system that we’re collecting the data in. So we define the team members, who’s all going to be in the team. The other thing that’s very important is what’s the requirements for PPE, Personal Protection Equipment. Of course, normal is hard hat, safety glasses, hearing protection, long-sleeve shirt.

Kelly Paffel: In a lot of cases, we’re using Nomex. Nomex is a fire-retardant coveralls. So we define out in the SOP for the PPE equipment and we’re also looking at maybe there’s other PPE equipment that might be required, goggles, face shields, high-temperature sleeves. So those are the other items that you always put into the SOP. Safety review for the team members, areas are going to be accessed. Do we need to check into the control room? Do we need to sign in? Do we need to put our names onto the board so that they know that we’re there? And then also we have a job risk assessment. Some plants have their own forms that they do for a job risk assessment. We do own form so that we do a job risk assessment for all the team members. So identifying a risk that might be out there and the SOP kind of goes through the guidelines that we want to see put their information, put on to the risk assessment.

Kelly Paffel: So, steam trap station testing, again, other devices that might be required gas monitoring, what types that we might need, H2S monitors, anything else, bomb testing the monitors, who’s going to do that, we’re going to do at the plant, where the bomb testing going to be done. Then we get into types of lift ladders and other methods to reach a steam trap station in higher elevations. So the SOP will go through … all right, if we’re going to use lift ladders, who is qualified to operate because that’s part of the SOP and what type of safety harness that they have to have, or is a plant going to provide the safety harness. That’s all part of SOP, getting prepped for the steam trap assessment. So, then it goes into the equipment. Of course, flashlights is a necessity. One of the things with the flashlight is intrinsically safe. A lot of the locations that we go into, we have to have intrinsically safe equipment. So we’re looking at making sure a flashlight devices are intrinsically safety.

Kelly Paffel: What unit are they going to be using? They’re going to be using UE 9,000, 10,000, or 15,000. If I’m going to use a UE 9,000, when’s last time it was calibrated and do I have the calibration documentation. The stethoscope module, one of the things in there [inaudible 00:10:44] make sure the stethoscope module is calibrated to that unit. Do we have extension? Do we need more extension? So, it continues on the equipment that we’re going to use. There’s other accessories, the umbilical cord for the stethoscope module can be used. We might use a painter’s extension rod to get up to higher locations, but again, that’s listed out in their SOP. Our infrared units, again, we want the calibration documents, we want to know the target area, so people will know that they’re using X unit, that the target area is going to be X diameter at this distance.

Kelly Paffel: So when they’re taking temperature measurement for that, they know what their target area is. The other thing that an infrared units are setting up the emissivity. So there’s a emissivity check to make sure the unit is set correctly. One of the most critical thing is this holster and other pockets. So we got to carry this equipment. Now, how do we safely carry the equipment on into a plant to do the steam trap assessment? The SOP lays out the devices that we have, holsters and other pockets depending on the team member and what they’re going to be doing. One of the things that we found that is going and purchasing a utility belt that’s very wide is more comfortable with holding the holster and the other equipment in a normal daylong steam trap assessment out in the field. So, those are laid out into our SOP.

Kelly Paffel: Again, equipment, clipboard, how to identify the steam trap location, we’re going to do assessment, we need to understand how do we get the people that is going to do the repair replacement, how do we get them back to that location. One of the things is that we’re going to tag. Their certain tags are acceptable, certain tags are not. So we identify what tags are going to be used and how we’re going to secure the tag to the steam trap. Typically, that’s done with a wire or chain method. The other thing that’s used today is pictures of locations. So identify the steam trap and the SOP goes through, okay, the picture will be taken, this is the numbering sequence, this is how to put the picture into the correct file for access to link it with the steam trap identification number, so that’s laid out.

Kelly Paffel: Data logging, what format, are we going to put the information to Excel, are we going to put the information to SAP or the plan maintenance system at the plan, how do we gather this information, and what do we do with the information. Once that we have gathered the information in the plan, we need to put in some type of software system so we can pull it up each time that we’re going to go back out and do the steam trap assessment. Information, what information is required? Location, of course, manufacturing, model number, connection size, connection type, internal orifice diameter of the steam trap, the operating pressure. And then continues on, we lift out downstream pressure, what type of condensate-return system, that’s the steam trap discharging and to how to evaluate the inlet pressure for the steam trap if it’s on a modulating system.

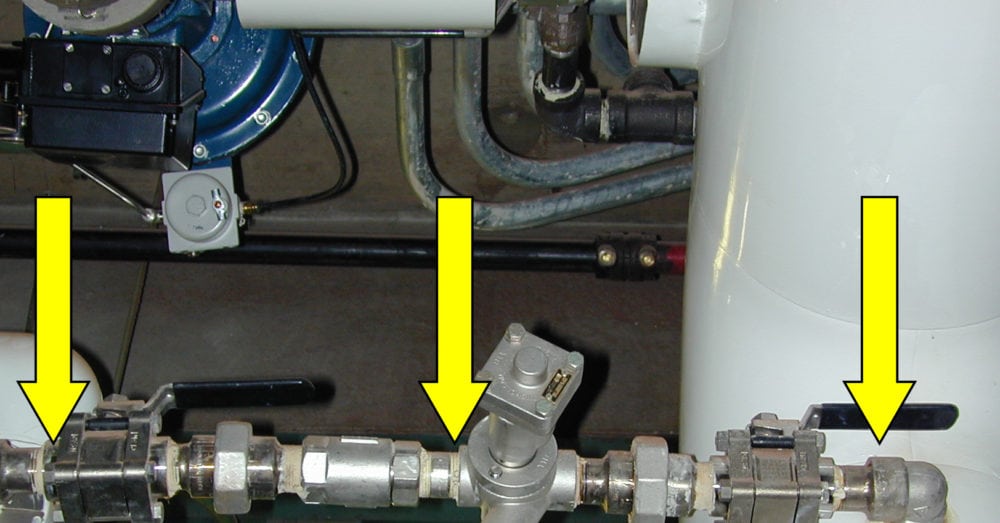

Kelly Paffel: Again, it goes into … they’re telling that people, a team members how to gather each piece of information so we get accurate information. What to do with the data? We have handwritten sheets that typically go and the field is done with data loggers out in the field. We’re bringing this information … I was kind of briefly talking about this before. We input it into Excel, or do we input it into Microsoft Access, or plant, a PM system or SAP system. We have to do something with the data and how do we evaluate one assessment versus the next assessment so we can find issues with steam trap stations are repealing, failing out there in the plant. Before starting it and the SOP kind of go through make sure that the people understand that before getting started is that we find failed steam trap station and we always say stations not a steam trap because steam trap stations are made up on isolation valves, strainers, blowdown valves and could be double blocking and bleed valves.

Kelly Paffel: It depends on the plant requirements but make sure the plant or yourself has a standard for replacement of a failed steam trap. Go on go and do a steam trap assessment without having a roadmap or documentation of what a replacement steam trap station should look at. Diagram here is a double block-and-bleed valve so we can work on the steam trap with the steam line in operation. All steam traps need to have a strainer and the SOP kind of goes through guidelines on twinkling a strainer for a steam trap and the steam trap testing assessment group will have somebody that’s capable opening a valve which is the blowdown valve on the strainer and blowing down the strainer make sure it’s clean and in good operating condition, but that’s one of the other things.

Kelly Paffel: In the SOP, we outline the meetings. We always want to have a pre-meeting with everyone to kind of lay out the objectives and the target areas that we’re going to be doing the assessment. And then follow up our daily meanings, daily meetings of what we covered the previous day, and what we’re going to cover that day, and what we might need for plant personnel involvement, maybe production people getting involved with us, and maybe power people getting involved, but those daily means are very important. We have them detailed what we want to cover in the SOP. And then, of course, post-meeting, once were concluded is having a post-meeting with all the team members that were involved in the plan to go through and this is what we found and these are some of the highlights of the assessment which was follow up by a full report again with this outline in the SOP.

Kelly Paffel: So, SOP kind of goes through the meetings. We’ll go through the steam trap testing which is methods, visual, temperature, ultrasound, although the comment that I always get people to ask me is what’s the best method. I always tell them using all tools available, visual, temperature, and ultrasound. Each method needs to be detailed in the SOP. People ask me visual, what do you mean visual. Okay, visual is installation. So when I go into a plant, I’m looking at steam trap stations, 10% of the steam trap population is installed incorrectly. I’ve multitude of times find steam traps are installed backwards, upside down, not in the correct position. The other thing that we’re looking for is the correct materials for the steam pressures. In steam systems, we’re going to need the code B31.1 which is national Power Piping Code. Too many times we find the steam traps do not have the pressure rating or the correct materials for the operating pressure of the steam system.

Kelly Paffel: That’s a code violation. So, visual tells us that the correct materials are for the pressures that we’re operating at. Discharge is open to atmosphere. If it’s open to atmosphere then you can visually see if the steam trap is working properly or not by the discharge to atmosphere. So visual testing is very important. The other thing is, is you can see in the picture here the steam tap discharging. One of the things you have to detail to the team members. That’s why I’m going to do visual testing as this steam trap is discharging to atmosphere. There’s understanding the higher pressure, the more flash steam that’s going to be generated. So this steam trap here is generating a lot of flash steam because it’s operating at higher pressure, and that go down and lower pressure so there’d be less flash steam generated.

Kelly Paffel: Why that’s important is we want to be able to team members to understand if the steam trap is discharging flash steam, or is it blowing steam through during a cycle process. So, that kind of detailed out and takes experience, of course, but the more you do it, the more proficient you get at it. So, visually, testing a steam trap is very good if the steam trap is pointing to everywhere. You can visually tell that. It’s visually testing. With normal operation, determining what the difference between flash steam and leaking steam. The next is on the left side, there’s a visual indicator. This visual indicator is looking at flow coming down and the glass should be about half steam flow to the steam trap and half, I kind of say, flow going down to. This is very important when it comes to checking process steam traps, this understanding the evacuation process.

Kelly Paffel: On the right side is a visual indicator of a steam trap. Different countries, if I go down to South America, the steam trap, the visual indicator is quite common and North America is not common to find this type of a steam trap with a sight glass into it. So a steam trap level is where the red mark is showing, there’s where the level, yes. So, we can see the modulation of the steam trap as its operating. So, it’s a very good test method, but it’s also associated cost with it. The other thing has the pressure rating of the glass. So there’s positive and negatives to everything. So, you must weigh causes, a negative but does it give you an indication, I kind of say, drainage, could be the positive which outweighs the negative which is cost. The next is temperature testing and I basically mentioned it as emissivity may contribute emissivity and the SOP goes through and there’s a procedure that’s outlined in the SOP to check the emissivity and target area.

Kelly Paffel: So, as you go up and cost with infrared units and target area gets smaller because the object is much better. The SOP also needs out to allowing the different testing procedures. The thing with the testing procedure is the inlet temperature equals the steam trap temperature. The steam pressure 150 psi, it should be 366 degrees or the steam trap temperature. In this example is a modulating steam to a process application. The temperature after the control valve was 299 degrees Fahrenheit and the SOP gives them some training method for checking temperatures and that steam trap is 293 degrees Fahrenheit. So the inlet temperature process and the steam trap temperature should be pretty close or equal. So, again, we have examples in our SOP kind of describes so team members can go back and reference to it or briefs themselves on the temperature testing methods.

Kelly Paffel: The next is going through the settings on the ultrasound unit, what kilohertz setting that we should be setting, the units up for understanding briefly how to adjust the sensitivity of the ultrasound unit and the operation of the different types of steam traps and the ultrasonic ultrasounds that will be emitted from the different types of steam traps. This is very detailed because there’s three major different groups of steam traps which are mechanical, thermodynamic, and thermostatic. We have to make sure that the people understand the testing procedures for each one of those three groups of steam traps. So the SOP outlines how we move forward after the actual assessment is completed and priorities that we set up. So, the thing is, is that we’re going to go out, we find 150 steam traps. Well, I’m not going to go out and fix all 150 steam traps instantaneously. So I want to set up priority levels which sure the steam traps are causing me the most problems.

Kelly Paffel: That’s priority ones, and then twos, and then threes. Sometimes I set a priority size. The other thing is, is that once we determine failure, it’s how do we eliminate failures. So part of the SOP is determine the component that is also to eliminate failure. On any steam trap assessment, the goals of steam trap assessment is to have a failure rate of 3% or less of a steam trap population. So when I go out and do a steam trap assessment, I don’t want to see 12% failure rate or 10% failure rate. I want to see a 3% failure rate or less. But to eliminate failure, you have to understand what caused failure. That’s a very, very important aspect of it. So, the thing is that root cause analysis becomes a very critical part. To perform the task, the SOP need to lay out how many test points are required to perform the test.

Kelly Paffel: On the lower left-hand side, there’s a test one upstream, test two downstream, and test three downstream as close as possible to the discharge or for the steam trap is that’s where you can find the highest degree of ultrasound generated is downstream of the discharge orifice of the steam trap. The thing is why do we take upstream, downstream is to make sure that we’re not taking up competing ultrasound that possibly could be in the system. Now, if you look on the right side, there’s a multitude of different test points, test point one, two, three, four, and five. It’s not limited to three. You can use up to five test points or you can use eight test points, but you need to do test points and make sure that you’re not picking and competing ultrasound. One thing I find with the testing teams is that they can … they say, “Well, we’re picking up with this sharp revving sound in a steam trap.” It’s not that. It’s the check valve downstream of the steam trap.

Kelly Paffel: That’s why we use multiple ultrasound readings upstream and downstream to find competing ultrasound. So it’s very critical to use a comparison method. That’s outlined in the SOP. The other thing we define is what the test results going to be, what’s proper operation, blowing completely failed, leaking steam. One of the things is, is that not in service. You have to define this in two ways, not in service, steam trap station valves are closed. The steam trap should be in operation and steam trap is critical to the steam system. One of the things that [inaudible 00:28:00] is walking into plants and they turn off steam line, drip-like steam traps and said, “Why did steam trap have failed?” But shutting it off is not a solution and that’s creating an even greater problem because one of the things that that steam trap is designed to drain out to condensate and the steam line during operation.

Kelly Paffel: If do not drain that, you can get severe water hammer. It’s not uncommon for steam systems to have explosions due to water hammer because somebody shut off a main steam line trap. So, when I go and look at reports from assessments and they have not in service but they don’t tell me it should be in service or it was the next one not in service is the second … this process is not an operation, non-critical to the steam system. So, here I go by and the shell and tube heat exchanger is not being used because they’re not running that product, that’s fine. That can be put in a not in service. So you need to define how you’re going to label the steam traps and there’s a common problem they find this not in service and defining that these steam traps should be in service. So, anyway, cold, steam trap is plugged; check valve is failed shut, steam trap failed closed position, just another way of describing the failed component.

Kelly Paffel: The other thing goes through on the SOP is the different configurations the steam traps. We have Maureen just giving a brief example right here. Where to place the stethoscope module when you’re testing for the steam trap because, again, I want to be downstream of the discharge orifice. That’s where I’m going to pick up the highest degree of ultrasound that’s going to be generating and that’s where I want to be testing it. So we go through and show and the team should be carrying a sample, the diagrams like this with them so when they walk up to a steam trap, they can identify it as inverted bucket mechanical for thermostatic, thermodynamic thermostatic, bimetallic thermostatic or both thermostatic, so then it’s been what type of steam trap they have and where they should be putting the stethoscope module.

Kelly Paffel: Two types of operation, let me go into steam trap. Since one is on/off operation, so when going up to the tests, the SOP would define, “Okay, it’s inverted bucket, thermostatic, and thermodynamics.” It goes in to find what the ultrasonic readings are going to be for the inverted bucket, or to the ultrasonic reading that’s going to be for the thermostatic, and what are the ultrasonic reading is going to be for the thermodynamic, how they perform. Thermodynamic is a very fast-acting on/off operation and a bellows thermostatic is very slow on/off operation, but the SOP that go define the two types of operation and what the ultrasonic readings are going to be for each steam traps. So they have this document, and they can take document with them, and then question what the reading is telling them. They can go back to the SOP, and check, and see what the dynamics of that type of steam trap should be with ultrasonic readings.

Kelly Paffel: The other one is a continuous flow type steam trap which is probably a little bit more difficult than the other type of steam traps that do testing because there’s two different testing points on steam trap. One is the mean discharge orifice which is located at the bottom of this diagram and the other ones, the air venting mechanism which is located the bottom and the SOP goes through how to test both of those discharge orifices and to understand the performance of each one during operation startup and in failure mode. So the SOP not only goes through what the steam trap ultrasonic readings temperature measurement should be during good operation procedure but also in the failures. If it’s leaking, these are the readings you’re going to get. If it’s blowing, these are the ultrasonic readings that you’re going to achieve. So, not only on the proper operation, you have to have the SOP go through and define the ultrasonic readings for leakage blowing steam. This we have to go through on two different orifices for what those readings would be. So the SOP will define each one.

Kelly Paffel: So, conducting a test and inverted buckets on/off and on here, it’s a UE 9,000 and the steam trap is in the off position you see deflections of up on the meter and when it discharges, it comes back down. Okay, “Where do I set the sensitivity?” Sensitivity is said based on your comparison test point. That’s critical because I can set up the sensitivity, make all your steam trap fail, I can set up the sensitivity and make all your steam traps fail. So it’s understanding where to set that sensitivity and the SOP goes through that defines that it’s in three pages long, defying that sensitivity and how to set it up because we want accurate measurements. We want testing to be 99% accurate. That’s goes through there. So, I just briefly said it before, the SOP needs to review each of the failure modes and how the failure mode will be detected. Here is an inverted bucket. That’s the lever mechanism failed, detached, and it’s blowing steam through, and the indication of meter will be high level readings, steady no on/off operation.

Kelly Paffel: So the SOP needs to find, again, not only good operating steam traps but also steam traps that are in the failure, different failure modes. The next is root cause analysis is part of the SOP is take the steam trap apart, visually inspect the steam trap after it’s been detected into a failure mode and how to document the failure and the correction methods for the failure. So, not only what failure occurred but the changes that need to occur to prevent further failures with the steam trap station. So, that’s all defined in the SOP. Root cause analysis has to be done with each steam trap that’s in the failure mode so we understand what caused a failure and institute change into the operations that prevents and improves failure. The steam trap station assessment failure, seeing assessment, testing failures all the time, one of is no SOP has developed or implemented. Therefore, there’s no training, no tools, no documentation.

Kelly Paffel: So, if you don’t have the training tools or documentation, there’s no reason to start. Early in my career, I work night shift and the power operations get myself through school. They decided to have me go on testing trip. So they give me a ultrasonic unit, no training. And so, I read the instruction manual. I go out, I didn’t even know what a steam trap was. So, how proficient or how accurate was my testing going to be? Very, very poor, extremely poor. So no training and the tool I was using wasn’t that great of a tool, and I was told not to do any documentation. So, what was the reason for us to be out there just to do it. So the thing is, is that that’s the key thing for a successful program is to have a well-documented SOP. So, kind of SOP and I always tell people today is a great day to get started, maybe tomorrow, okay, but we have to get started.

Kelly Paffel: How to get started is start to develop an SOP. The thing is, is that if you have questions or whatever, here’s my contact information. Please contact me. Let me help you achieve a correct SOP. So you get accurate test assessment of 99.9%. I think that can be achieved. So, thank you for your time today and I’ll turn it back over to you, Maureen.

Maureen: All right, awesome. Yeah, we definitely want to avoid people just being handed a piece of equipment and say, “Here, go, do,” and have no understanding or reporting back. So this was really good information. So definitely, if anybody has questions, as you see, he’s got his contact info there but if you want to type those in so we can … everyone can benefit from the questions you’ve got. I did have a couple come in already though, so we’ll toss those over to you now. So someone was wondering, how you get the orifice size if there’s no nameplate on the steam trap.

Kelly Paffel: Well, great question. The only way is to take the steam trap apart and check the diameter of the office with a measurement device. So that’s a difficult one. The thing about it is, is that when you’re purchasing steam traps, make sure you have … the steam trap is well-documented on the body of the steam trap of what orifice is inside that steam trap because some of the steam trap is mechanical specific. It’s specifically a very sensitive to pressure ratings of the orifice. If you exceed the pressure rating of the orifice, the steam trap will come in to the off position and stay off and could generate severe water hammer.

Maureen: All right. And then let’s see, what’s a good rule of thumb for how often should an inverted bucket trap cycle … I’m eating my words here.

Kelly Paffel: No problem. A rule of thumb, 15 seconds in the off cycle. So, if it’s like it goes faster than 15 seconds, it’s undersized. So inverted bucket should cycle no faster than 15 seconds. Now, an inverted bucket can stay after 15 minutes. One of the things when it’s staying in the off position for a long period of time, it can lose prime. So you have to be a little bit careful with oversizing inverted bucket. But more so, people I find under sizing more of a bigger problem. So you want it to be in the off cycle for 15 seconds.

Maureen: All right, awesome. Okay, well, that’s all the questions that so far have come through. So maybe everybody’s already started working on their procedure. Oh, wait, here we go. Someone just typed in, “How often is thermostatic cycle?”

Kelly Paffel: Well, thermostatic steam trap is similar to the inverted bucket. We do not want it to be cycling fast because that means the steam trap is oversized, not undersized, oversized. We call that short cycling and that will limit the longevity of the thermostat bellows or bimetal configuration. So we want the thermostatic trap to be off. So, 25 to 30 seconds for the rule of thumb cycle and then be off again for 25 to 30, 30 seconds.

Maureen: All right. Now, we’ve got the cycle questions going. So, someone now is asking about how often that for a disk trap, what the cycle is on that.

Kelly Paffel: 12 seconds or less. We consider the steam trap to be in a failure mode which is going into what’s called machine-gunning term, a rapid cycle. In a disk type or thermodynamics design, there is a steam loss like starts to do the fast cycling. So, that time period, we consider it to be in a failure mode. They’ll fail shortly but we consider it a failure mode.

Maureen: All right, cool. Well, let’s see. How often is testing needed for street steam traps for cost savings, or is that kind of up in the air?

Kelly Paffel: The steam trap testing is, is that you have to define in the system which steam traps if in a failure mode are going to cost you energy. The thing is people saw 200 psi steam trap is going to cost me $15,000 a year. It depends on where the 200 psi steam trap is discharged. If it’s discharging into a flash system, it’s not really costing anything except the mechanical energy if you’re using a turbine for pressure reduction. So you really have to define in the plant which steam traps if in the failure mode are crashing you energy and the second thing is if it’s going to cause you a system operation. One of the things when you start a steam trap assessment program and is the failure rate is 25% then you should be doing it every month and to define out where the failure is occurring and how fast they’re occurring.

Kelly Paffel: Once you get to a 3% failure rate then we go and define how often we test steam traps by other measurements, the one that’s doing pressure ratings on counterfeit lines, the counterfeit line with all the steam traps working correctly is at three psi and if that pressure increases to five psi then we know we have steam trap failures out there which are pushing and why steam into the condensate-return system creating pressure. So there’s indicators that we put into the system that tells us when we should be testing steam traps.

Maureen: All right. Now people got the juices flowing, so let’s see. Someone’s asking about the kind of temperature. So they said, “We have failure on thermostatic in the cold weather around minus 23 degrees. Is it because it’s not suitable for cold weather?”

Kelly Paffel: Well, the thing with thermostat is not on steam trap is you must know what the sub cool is. The sub cool on some of thermostatic design, steam traps can be 80 degrees Fahrenheit which will back up condensation cause failure and sometimes thermostatic design steam traps people put them too close to the process of which can back up constant in the process that can generate water hammer. So the thing is, is that here is your benchmark. Any steam trap that’s 250 psi or less should last you 15 years, period. If we have a steam trap failing within 15 years at 250 psi or less, there’s something wrong. You have to understand the root cause analysis, figure out what’s causing the problem and make the correction. But that’s your rule of thumb, 15 years, period.

Maureen: Okay. How can we decide the percentage of leak from a steam trap?

Kelly Paffel: Well, the thing is, is that, okay, so I say up a comparison method and depends on the ultrasonic units I’m using, 9,000, 10,000 is I come up with a comparison method and go to the discharge orifice and the discharge orifice, the ultrasonic reading level would be X, okay? Anything higher than that is the degree of leakage. Now, if we wait for the steam trap to discharge, I get X decibel reading out and that point from my comparison method that’s over that percentage of readout, it gives me my percentage of leakage through it, but actual flow is very difficult to deal.

Maureen: All right. Well, I think that did it for now. So everybody has Kelly’s information here and, definitely, you can be in touch with us as well if you’ve got further questions. Kelly, thanks so much. I’ve got just a couple closing slides here. So, as we kind of continue our month of anything and everything steam, next week we’re going to have Adrian Messer from UE Systems come and do a webinar on how to create a steam report in our DMS software. So, for those of you that are using our equipment and testing steam traps, he’s going to show you how you can pull those reports and use DMS. So, definitely, come and join us for that one. We’ll have an invite going out tomorrow, so everybody can get the link for that. And then we’re going to have Chris Colson from Allied Reliability come and do our final webinar at the end of the month. He’s really good at all things, energy, and energy conservation. So we’re looking forward to his presentation. Again, we’ll get an invite out for that next week.

Maureen: So, just kind of continuing on with our steam month. Of course, if you’ve got other applications other than steam that are of interest, we do have three different online training courses available now. Our mechanical inspection and lubrication, compressed air survey, and electrical inspection, just really great online courses that can be taken whenever, wherever and I don’t know that it’s going to be ready before the end of Steam Timber, but certainly, at the very beginning of October, we should be rolling out our steam online training course. So we’re really excited about that and you’ll certainly be hearing more about that here soon. Thanks to Kelly. He was helping us with the content for that as well. So it should be a really, really good course and, again, you’ll hear more from us soon.

Maureen: Definitely, I want everybody to stay connected with us. Hop on our LinkedIn groups, follow us on Twitter, questions that you, guys, have had from today. Those are good to toss out in a forum like our LinkedIn group just to get feedback from other folks how other people are writing their procedures, things that they’ve struggled with, things like that. I think those are great kind of community for sharing that kind of information. And then I’ll leave our contact info up here. Again, I did record this so we’ll have that recording up later today and everyone should see an invite for the DMS webinar tomorrow. If you don’t get it, just shoot us an email and we’ll be sure to get you signed up. Again, Kelly, thank you so much for taking some time out today and thanks to everybody who joined us. Hopefully, we’ll see you all back here next week.

Kelly Paffel: Thank you for having me. Have a great day!