HOW TO ACHIEVE RELIABLITY WITH ELECTRIC CONDENSATE PUMP UNITS

Do you want this article in PDF format? Download it here:

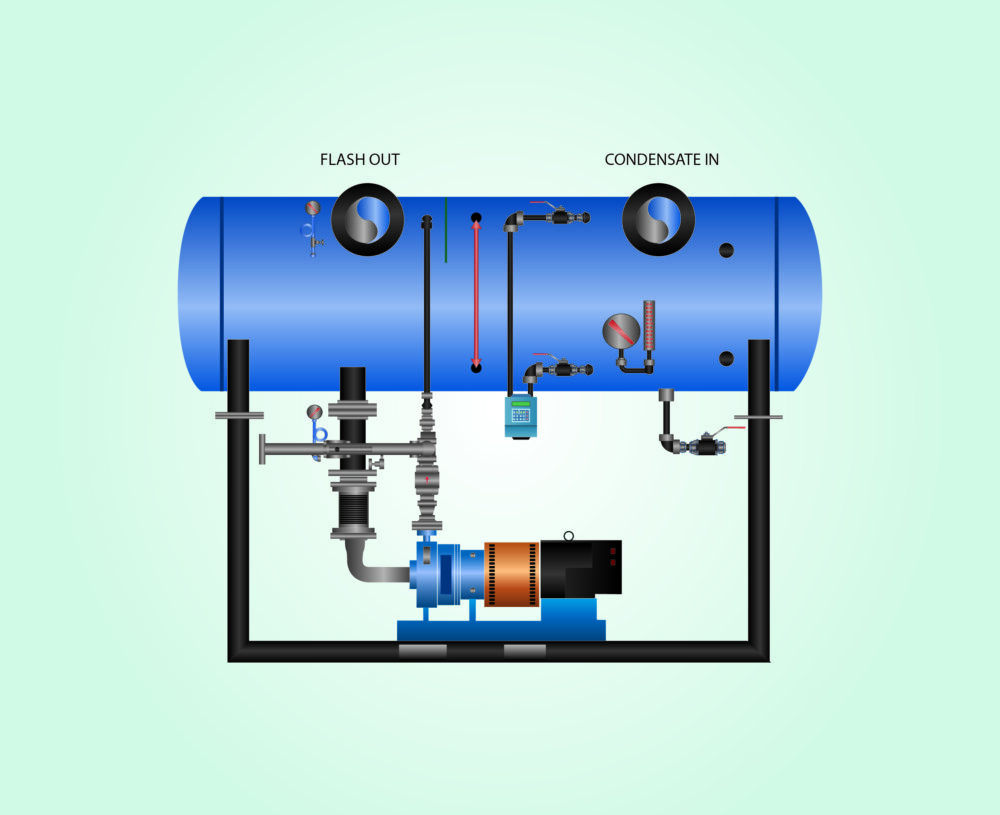

Download a PDFWhen pumping condensate, the first choice is an electric condensate pump unit over all other pumping methods. Electric condensate pump units consume less energy than other technologies used in pumping condensate. Pumping condensate is easy, because condensate is the purest water and is not an aggressive fluid found in process plants.

With the right electric condensate pump, 25 years of reliable operation is achievable.

However, plants worldwide struggle with high electric condensate pump failure rates because they select the wrong pump for the application. These failures are a major problem in condensate system reliability.

Remember that condensate systems operate at 211°F or above. Therefore, electric pumps must be able to pump condensate at these temperatures.

2. SELECTING AN ELECTRIC CONDENSATE PUMP

A critical factor in choosing the right condensate pump is net positive suction head (NPSH) because of the high temperature of condensate. NPSH refers to the minimum suction pressure, expressed in feet of water column, required to prevent the forming or phase change (flash steam) and collapsing of these flash steam vapor pockets.

The main cause of premature failures of electric condensate pumping units is that pumps cavitate because they lack sufficient NPSH.

A high percentage of condensate pumps marketed as “condensate pumping units” can only handle condensate temperatures of 204°F and below. Thus, these pumps suffer from cavitation and fail prematurely.

The plant must specify the condensate temperatures for all electric condensate pumps. If the minimum temperature specified is 211°F, pump cavitation and failures will not occur.

3. HOW TO PREVENT ELECTRIC PUMP CAVITATION

Understanding electric pump NPSH requirements is critical to preventing pump failures.

NPSH is determined by factors such as temperature, altitude, static head, and capacity. Electric condensate pumps specifically designed to handle low NPSH requirements for condensate systems are available, thus preventing cavitation. These pumps are able to operate at high condensate temperatures.

3.1. Cavitation

As liquid enters the eye of the impeller in a centrifugal pump, its pressure is reduced. If the absolute pressure at the impeller eye drops down to the vapor pressure of the fluid (condensate), phase change will occur or flash steam (vapor) pockets will begin to form and try to expand 1,600 times. As the flash steam (vapor) pockets travel in the fluid along the vanes of the impeller, the pressure increases, and the flash steam (vapor) pockets collapse.

This collapsing of the flash steam bubbles or pockets is called cavitation.

Cavitation is noisy and damages the pump impeller, shaft, and seal. Over time, it may also reduce pumping capacity. Seals are usually the first failure to occur from pump cavitation, but pump cavitation can easily destroy the pump’s impeller.

Figure 3 shows the change in system pressure (Ps) as the fluid (condensate) travels through the impeller’s eye. To prevent cavitation, Ps must remain above the vapor pressure. The top curve shows Ps remaining above fluid vapor pressure as it passes through the pumps; cavitation cannot occur. The bottom curve shows Ps falling below the vapor pressure as it enters the impeller eye, thus causing cavitation. The cutaway view of a pump in Figure 3 shows the passage of flow through the impeller.

3.2. What Determines NPSH

The following factors determine NPSH:

• Temperature

• Altitude

• Static head

• Capacity

NPSH = Barometric pressure (ft.) + static head on suction (ft.) – friction losses in suction piping (ft.) – vapor pressure of liquid (ft.)

NPSH is defined as a suction pressure minus vapor pressure expressed in feet of liquid at the pump suction. It results from the height of water above the pump suction.

Suction head = Total pressure of liquid entering the pump suction

3.3. Minimum NPSH for Condensate

The minimum NPSH for an electric condensate pump to prevent cavitation is 18”.

It is important to work with the correct condensate pump supplier to ensure proper operation and reliability.

3.4. Other Factors

Other factors must be considered in ensuring proper condensate pump operation.

• Avoid strainers before condensate pumps, which will restrict condensate pump suction piping and can reduce the available NPSH.

• Never reduce pipe sizing from the condensate tank to the pump’s suction inlet. Reducing the size of the piping restrict the suction and reduce the NPSH.

• Always work with the pump vendor to ensure the pump is operating in the correct position of the pump curve.

3.5. Two NPSH Values

There are two values of NPSH: NPSHR and NPSHA.

NPSHR (required) is the amount of suction head required to prevent pump cavitation. It is determined by the pump design and is indicated on the pump curve. It varies between different makes of pumps, including different pumps of the same design, and varies with the capacity and speed of any one pump. This value must be supplied by the pump manufacturer.

NPSHA (available) is the amount of suction head available or total useful energy above the vapor pressure at the pump suction. NPSHA is determined by the system conditions and typically is measured in ft. of liquid.

3.6. Calculating NPSHA

NPSHA can be calculated by using the equation below.

Subtract the vapor pressure of the liquid from the system pressure (Pa).

Convert the pressure from psia to feet by multiplying by 2.31 and dividing by the liquid’s specific gravity.

Determine the static head (He, measured in feet) by the elevation of the water line above the pump suction. This value can be negative if the application is a suction lift.

Finally, calculate the friction losses (Hf,, measured in feet) and subtract them from He.

Add this quantity to the first term of the equation.

Where

Pa = Pressure in the receiver in psia

Pv = Vapor pressure of the liquid at its maximum temperature in psia

He = Elevation head in ft.

Hf = Friction losses in the suction piping at the required flow rate in ft.

Spgr = Specific gravity

3.7. Pounds Pressure Versus Feet of Head

Each pound of pressure developed by a pumping system is equal to 2.31 feet of head. Therefore, 10 pounds of pressure (psi) will lift water vertically 23.1 feet.

This can be calculated for any setting using the following formula:

Pounds per sq. in. = head in feet / 2.31

Head in feet = pounds per sq. in. x 2.31

4. VENT SIZING FOR CONDENSATE TANKS

The vent for the condensate tank should be sized for the amount of flash steam that will occur in the condensate system. Also, the vent must have added capacity for live steam that may occur from a poorly managed steam system. If the condensate tank vent line is not sized properly, then the condensate tank will increase in pressure and the condensate temperature will increase accordingly. As a result, the condensate pump will not have sufficient NPSH for the high condensate temperature, and pump cavitation and premature failures will occur.

5. DEVON’S LOOP: CONDENSATE ATMOSPHERIC TANKS

All condensate tanks open to the atmosphere need a Devon’s loop. A Devon’s loop does two critical things.

First, it discharges condensate to a drain if the pumps fail and are not able to pump the condensate out of the tank. This prevents the condensate from traveling up the flash steam vent piping and spewing out high temperature condensate and causing a major safety hazard. Second, Devon’s loop prevents flash steam from venting through the loop during normal operation.