Compressed Air System Leakage Assessment in 12 Steps

Do you want this article in PDF format? Download it here:

Download a PDFCompressed Air System Leakage Assessment

Compressed air is one of the principal forms of energy used in industrial processes. It is often the most expensive when evaluated on a per-unit, energy delivered basis. In addition, compressed air systems typically develop operational issues and air leaks as they age. By implementing a thorough compressed air system analysis, the typical industrial facility can eliminate up to 22% of its compressed air energy costs.

Compressed-air system analysis consists of a complete review of the compressed-air system from the air intake to the end users, plus a compressed-air leak detection and correction program. To achieve success in your compressed-air system analysis, follow these 12 steps:

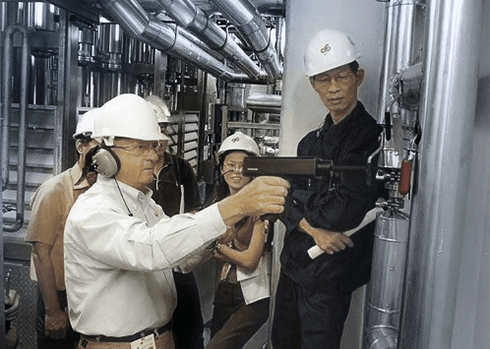

1. Conduct a walk-through of the entire plant or specific areas to be reviewed. This will single out some of the issues or major areas of concern that demand a higher priority. Pay special attention to areas that require regular human interface, such as quick coupling points, regulators, oilers, drip traps, filters, and areas where plant personnel work. High compressedair leakage typically occurs in these spots.

2. Set clear goals for the analysis. Examples include:

- Get everyone involved. The most effective programs involve all levels of plant personnel.

- Eliminate the need for one or more air compressors.

- Understand the system’s needs and requirements.

- Determine the air-pressure requirements of the system.

- Benchmark the different components of the system.

- Compare different types of connections. Different types of connections leak at different rates.

- Determine the projected cost of the program and document the (loaded) cost to produce the compressed air.

How many goals are best? Define and document no more than three major objectives or goals to be accomplished during the system analysis. (Example: removing one or more air compressors from operation by increasing the reliability and efficiency of the compressed-air system.) Define and document no more than four minor objectives or goals to be accomplished during the system analysis.