Best Practice No. 77 What is the Correct Reliable Condensate Pumping Unit

Do you want this article in PDF format? Download it here:

Download a PDF1. Why Have CONDENSATE Pumps?

In gravity-type systems the condensate lines do not have the pressure to flow the condensate back to the boiler operation; therefore, there is a need to have a vented condensate pumping system. Another common application is the main collection point in the boiler operation, where there is a need to collect the condensate and pump the condensate to the deaerator system.

In low, medium, and high-pressure systems there is a need for condensate pumps depending on the design of the system.

- Low-pressure steam system

- Modulating process steam system

- Process temperatures below 220oF

- Elevated condensate headers

- Condensate line distance to a main collection tank

- Condensate return line pressures

- Main collection point

2. Types of Pumping Systems:

There are different types of pumps for the different applications found in the steam and condensate system.

- Electric (on-off operation)

- Electric (continuous flow operation)

- Steam motive type pump (self actuating)

- Air motive type pump (self actuating)

2.1. Electric (On-Off)

As the condensate level in the tank increases to a certain level, contacts close in a float switch and start the condensate pump. The pump operates, until the condensate level decreases to a point that the float switch contact opens and the pump stops. This operation repeats as the water level rises and falls.

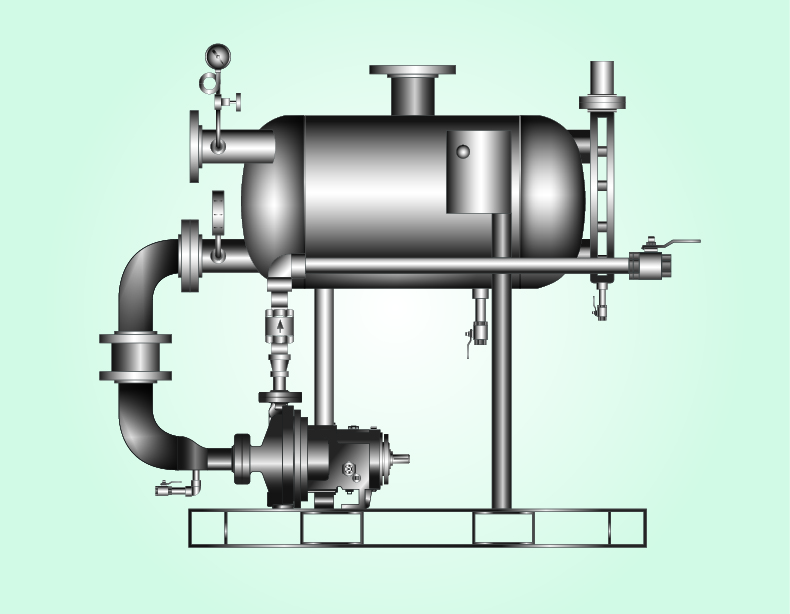

One of the most common pump systems is the floor-mounted horizontal tank with one or more pumps mounted to the side of the tank. It must be understood that this design is usually operated at temperatures below 205 degrees F. If the temperature is higher the pumps will cavitate and malfunction.

The pump is allowed to operate at a nearly constant

head-capacity point and not over the entire pump curve as with continuous operation.

- Condensate capacities of 12,000 lbs per hour or less

- Single pump or dual pump

- Gravity systems, low pressure or medium pressure return system

Advantages:

- Low cost

- Simple operation

Disadvantages:

- Low condensate temperature operation (below 205oF to 180oF)

- Low capacities

- Surging in the condensate lines during pumping mode

- High pump cavitation due to lack of proper NPSH

2.2. Electric (Continuous Flow)

The condensate level is controlled by a modulating valve, which regulates to keep a constant condensate level in the tank. As the demand increases and the level start to increase, the valve opens further to let more condensate flow though the valve into the condensate return system. As the demand decreases and the level begins to drop; the valve closes down and reduces the amount of condensate being discharged.

The condensate pump operates continuously and pumps against the modulating valve. The flow corresponds to the pump performance curve at various discharge heads relating to settings of the modulating valve. Continuous operation is more suited to centrifugal pump operation, which allows for wide capacity changes over a smaller change head pressure. Also, the horsepower does not increase as a pump is operating against a nearly closed modulating valve, which can occur during operation.

Continuous flow pumps should have a by-pass orifice or recirculation valve. These devices will recirculate a required flow back to the receiver, if the control valve on the discharge side of the pump closes to prevent the possibility of pumps overheating or cavitating. Minimum By-Pass Sizing –Consult your pump manufacturer for assistance.

- Condensate capacities above 12,000 lbs per hour (high capacities)

- Single pump operation (most common)

- Gravity systems, low pressure or medium pressure return system

Advantages:

- High condensate capacities

- Handles condensate load variations

- Continuous flow of condensate in the return system, therefore no surging in the condensate lines

- Easy to obtain the correct NPSH for the electric pump

- Low operational life without failures

Disadvantages:

- More complex with a large number of components

- Higher initial cost

2.3. Steam Motive Condensate Pump (Self Actuating)

The operating force to push the condensate out of the pump is steam.

Since the steam motive pump handles a low volume of condensate at each stroke (push), the applications are somewhat limited for the pumping unit

The steam-powered pumps can be used in a closed loop system or a vented system to atmosphere. In a closed loop system, a steam trap must be installed at the discharge of the steam motive pump unit.

A vented receiver or collection header is an essential part of the installation, as any flash steam must be separated from the condensate before it reaches the pump assembly.

- Condensate capacities of 12,000 lbs per hour or less

- Gravity systems, low pressure or medium pressure return system

- Pressure reducing valve needs to be installed on the steam motive steam supply to regulate the push cycle

- Close systems – the receive tank needs to be ASME pressure vessel rated

- Motive steam head mechanism needs to be rated for the maximum steam pressure – steam motive pressure

- Safety valves are typical on the steam motive line to meet the steam motive head mechanism pressure rating

- Safety valve has to be installed to ASME B3.1 code, recommendations, safety valve manufacturer recommendations and steam best practices

Advantages:

- Low cost

- Simple operation

- No electric is required

- Used in explosion proof areas

Disadvantages:

- Low capacities (12,000 lbs. per hour or less)

- Needs a condensate fill head or receiver

- Mechanical failures of the mechanical mechanisms

- Venting on flash steam in the condensate (vessel) chamber is limited

- Needs a pressure reducing valve

- Steam pressure ratings on the components are low and units require a safety valve to be installed per ASME recommendations

2.4. Air Motive Condensate Pump (Self Actuating)

The operating force of this type of pump is compressed air, and the consumption is very low. Since the pump handles a low volume of condensate at each stroke, its applications are somewhat limited.

It is not recommended that these types of pumps be used in groups to handle larger condensate loads.

- Condensate capacities of 12,000 lbs per hour or less

- Gravity systems, low pressure or medium pressure return system

Advantages:

- Low cost

- Simple operation

- No electric is required

- Used in explosion proof areas

Disadvantages:

- Low capacities

- Air comes in contact with the condensate enabling oxygen corrosion

- Mechanical failures of the mechanical mechanisms

- Venting on flash steam in the condensate (vessel) chamber is limited

- Needs a condensate fill head or receiver

- Mechanical failures of the mechanism

- Venting on flash steam in the chamber is limited

3. Selecting the Correct Pumping System

Information required to select the correct pumping system;

- Capacity required

- Maximum

- Minimum

- Normal

- Tank sizing

- Flash steam, neglect of the steam system

- Required discharge pressure

- NPSH required due to the temperature of the condensate

- Control of the flow of condensate

- On/off or continuous flow

- Vent sizing

- If receiver is vented to atmosphere

- Location and installation

The plant needs to document the required capacity of the condensate pumping system. Condensate pumps are used in a variety of process and heating applications. The maximum load is never usually achieved and there is typically a great variance between the normal high condensate flow and the minimum condensate flow. Therefore, careful consideration must be given when defining the condensate capacity.

4. Sizing of Receivers

The receiver should be sized for capacity sufficient to allow condensate storage for a minimum of 15 minutes.

Example:

- 4,000 lbs. per hour (condensate capacity)

- 4,000 divide by 8.3 (lbs per gallon) divide by 60 (minutes in an hour) = 8.03 gpm

- 03 gpm x 15 = 120 gallon storage tank

The condensate tank material is typically a heavy wall steel tank or a stainless steel. In some cases, the condensate tank is coated with a corrosion-resistive material.

It is recommended that the tank be stamped ASME, even if the tank is vented to atmosphere, to provide a more desirable tank construction for industrial applications.

Rectangular Tank Capacity (C in Gallons)

C = Height x Width & length (inches)

230

Or

C = HWL (Ft.) x 7.5

Storage Capacity of Circular Tanks in gallons

Circular tank diameter-(D) in feet

Length – (L) in feet

Storage = 6D² x L (gallons)