Safety Valves in Steam Systems – Sizing and Installations, Best Practice No. 74

One of the most critical safety devices in a steam system is the safety valve. The safety valve provides a protective measure for personnel safety, equipment, and property from potentially dangerous high levels of temperature and forces caused by excessive steam pressure in the steam system.

Safety valves are a requirement by code and insurance requirements. Therefore, it is important to have good up-to-date records of all safety valves in the steam system. With readily available technology today, a database should be developed containing all the relative information of all safety devices in a facility. The safety valve database should be reviewed on periodic basis depending on plant standards, insurance company recommendations, and the local, state or federal government requirements.

The code that establishes the requirements for safety valves is governed by the American Society of Mechanical Engineers (“ASME”.) ASME, through its committees, has published and continues to update the Boiler and Pressure Vessel codes for safety valves. It is the responsibility of plant personnel, primarily the steam team, to know which codes apply to the different parts of the steam system.

The major considerations for safety valves are proper sizing followed by correct installation. A partial listing of sizing and installation highlights is listed below. More guidelines will be provided in future articles.

Sizing Guidelines for Safety Valves

- The set point for the safety valve is recommended to provide a differential between operating and set steam pressures of at least 20 %.

- When considering a safety valve downstream of a steam pressure control valve, the total capacity of the safety valve at the set point must exceed the steam control valve’s maximum flow capacity (largest orifice available from that manufacturer) if the steam valve were to fail open. The inlet steam pressure to the valve must be calculated at the maximum safety valve setting of the steam supply source, not the nominal operating pressure.

- It is important not to oversize a safety valve. Bigger is not better in this case because a larger than required valve could cause chatter, leakage and premature failure of the device.

- Many times, a single safety valve is not possible due to high capacity, physical limitations or economic considerations. An acceptable alternative method is to employ multiple safety valves on the same system. The valves should be of the same setpoint and the capacities must be equal to or greater than the rating of the equipment. Additionally, the vent pipe must be sized to account for the venting capacity of all the safety valves fully opening at the same time.

- The set pressure of the safety valve shall be set at or below the Maximum Allowable Working Pressure (MAWP) of the component with the lowest setpoint in the system. This includes but is not limited to Steam Boilers, Pressure Vessels and Equipment and Piping Systems. In other words, if two components on the same system are rated at different pressures, the safety device protecting both of these devices must be set at the lower of the two set points.

Installation

- The steam system must be clean and free of any dirt or sediment before commissioning the steam system with a safety valve.

- The safety valve must be mounted vertically with the valve’s spindle in an upright vertical position.

- The inlet steam piping to the safety valve must be equal to or larger than the safety valve inlet connection.

- There shall be no intervening shut-off valves located between the safety valve inlet and the steam component that could permit the safety valve to be isolated from the system.

- Drains or vent openings on the safety valve shall not be plugged or capped. They are on the safety valve for a reason.

- Safety valves are set, sealed, and certified to prevent tampering. If the wire seal is broken, the valve is unsafe and should not be used. Contact the supplier immediately.

- For multiple safety valve installations using a single connection, the internal cross-sectional area of the inlet shall be equal to the combined inlet areas of all the safety valves.

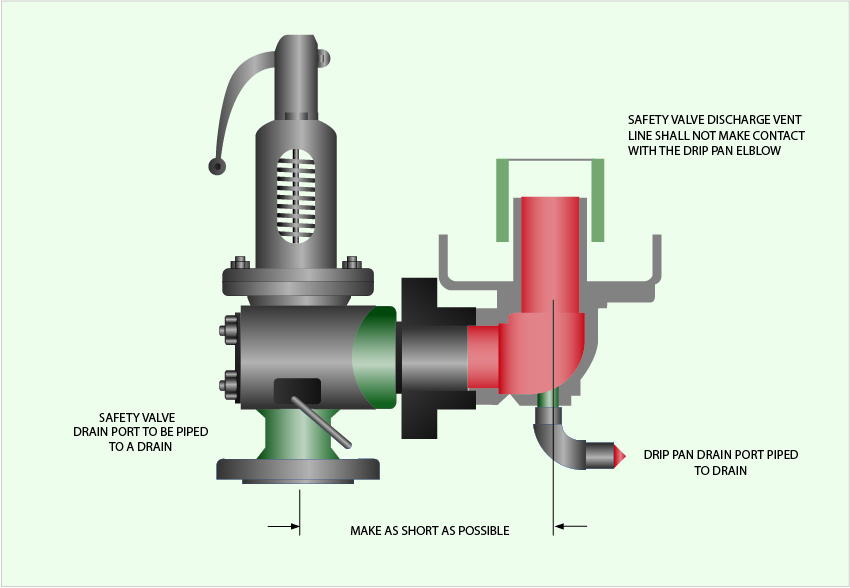

- All safety valves should use a drip pan elbow on the outlet. The drip pan elbow changes the outlet of the safety device from horizontal to vertical. Installation of the drip pan elbow has its own guidelines.

- Never attach the vent discharge piping directly to the safety valve. This would place undue stress and weight on the valve body.

- Safety valve vent pipe may not touch the drip pan elbow

- The drains on the drip pan elbows are to direct condensed vapor and rain safely away to the drain. Do not plug these openings.

- Steam will not escape from drip pan elbow, if the vent line is sized correctly

- Vent piping

- The diameter of the vent pipe must be equal to or greater than the safety valve outlet

- The vent line should be sized such that back pressure is not placed on the drip pan elbow

- Minimize the length of the Vent pipe.

- The discharge outlet of the vent pipe should be piped to the closest location where free discharge of the safety device will not pose a safety hazard to personnel. For a roof line termination, the vent should be no less than seven (7) feet above roof line. The top of the vent line should be cut at a 45 degree angle to dissipate the discharge thrust of the steam, prevent capping of the pipe and to visually signify that it is a safety valve vent line.

The proper selection, installation, and use of safety valves require a complete understanding of ASME code and any additional requirements adopted by insurance companies or the local jurisdictional authority.

Show a picture of an incorrect installation and a correct installation.

Best Practice:

- Database all safety valves.

- Review all safety valves should be reviewed on periodic basis depending on plant standards, insurance company recommendations, and the local, state or federal government requirements.

- Institute plant standards for safety valve installation and selections Best Practices.