No. 63: Steam Warm-up Valve

Do you want this article in PDF format? Download it here:

Download a PDFBEST PRACTICE NO. 63

STEAM WARM-UP VALVE SYSTEM FOR A SAFE, RELIABLE STEAM SYSTEM OPERATION

READ FULL PDF TECHNICAL PAPER – CLICK HERE

1. IMPORTANCE OF A STEAM WARM-UP VALVE

A steam system warm-up valve is an essential part of the steam system. The initial startup and warm up of a steam system are when the highest condensation, or liquid, will occur in the steam lines with all the thermal expansion of the steam line. Therefore, to ensure a safe and reliable steam system operation, the steam system must have a predetermined time frame for warming up, with a slow ramp up time to the desired temperature and steam pressure. A steam system warm-up valve is a necessity on all isolation valves that are 3” or larger, in pressure-reducing valve (PRV) stations, and in a few process applications.

A lack of the proper steam system warm-up valves can have several negative effects on the system.

1.1. Too Fast of a Steam System Warm-Up

If the system has a high rate of steam flowing into a cold system, water hammer will result, causing component failures and even major component failures, such as failures in steam lines, elbows, valves, and more.

If any component fails, plant personnel can be in harm’s way. Therefore, a warm-up valve needs to be part of any steam system installation for safety reasons.

1.1.1.Using Force to Open a Valve 3” or Larger

Plants use gate valves for isolation in the steam system. A gate valve will have a force on the (P1) steam inlet side of the valve in the shutoff position, which will put extreme forces on the valve gate inlet, thrusting the gate into the valve seating surface. With a high steam pressure or force on the inlet side of the gate (P1) and zero pressure on the outlet of the gate (P2), plant personnel must use excessive force to open the valve unless they equalize the pressures across the steam valve.

To open a steam valve without a warm-up valve, personnel typically use external force, such as a large pipe wrench or a “cheater bar” (a nickname for devices that open gate valves).

Using this type of force on a gate valve is a very unsafe practice that can lead to injury or death. Steam valves are not designed for external forces, such as large pipe wrenches or cheater bars, to be used on them. External force can damage the steam valve, and a major failure can occur that immediately releases the steam to the surrounding area.

If the steam pressure is equalized around a warm-up valve, the steam presure at P2 (outlet) will counter the inlet forces on P1, and the gate valve will rise without using external forces.

1.1.2. Other Isolation Valves (Butterfly or Ball Valves)

If the plant operation uses a butterfly or ball valve, which are quarter-turn valves, for steam isolation applications, then warm-up valves are essential to bring the steam system up slowly to the operating steam pressure. It is impossible to warm up a steam system slowly by using a butterfly valve or ball valve that is 3” or larger because the valves are quarter-turn valves. The preferred valves for steam isolation are butterfly and ball valves, but warm-up valves are essential for these types of valves.

1.1.3. Valve Damage

Any large isolation valve used to warm up the system will experience erosion to the valve trim or wire drawing. Therefore, after the valve operates once or twice, steam leakage will occur, and the valve will not perform its function of isolating the steam system.

2. What is a WARM-UP valve?

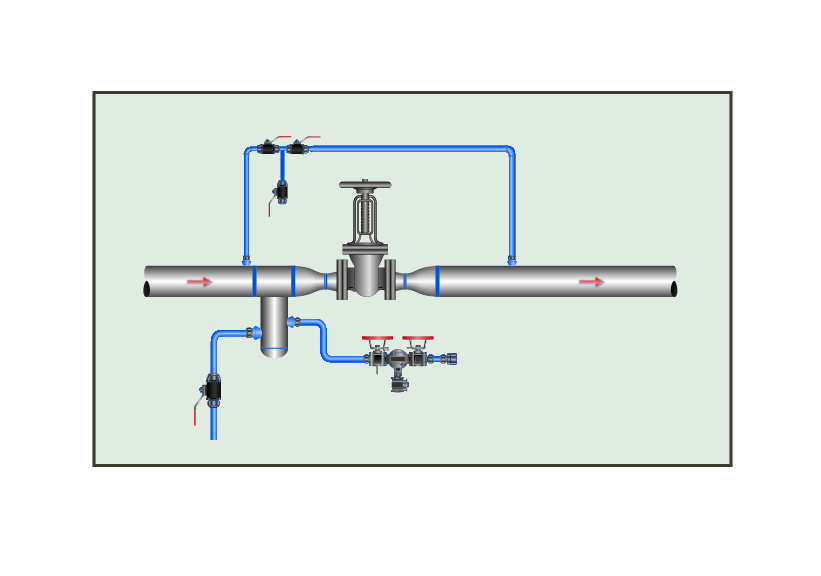

A warm-up valve is a smaller steam valve installed in a pipe or, use of tube material in a bypass loop configuration around a 3” or larger isolation valve or installed in a PRV station. Some other special applications may require a steam process warm-up valve.

At startup, the steam warm-up valve is operated before the larger valves (isolation or PRV valves) are operated to allow the steam system to warm up gradually. The slow process of allowing steam to flow downstream in a controlled way allows the steam pressures to equalize on both sides of the isolation valves. The equalized steam pressure enables easy opening of the larger valves, eliminates thermal shock (water hammer), and eliminates all other problems associated with trying to open large steam valves with high pressure differentials.

The rule of thumb for the time it takes to warm up a steam line is 1 psig per minute but taking more time than the rule of thumb is always better for the system.

3. What Size Warm-Up Valve?

When installing an isolation, shutoff, or bypass valve on the steam distribution system (3” or larger), it is necessary to install a small valve (½”, ¾”, or 1”) around the isolation valve. The proper size of the warm-up valve will depend on the length and diameter of the steam line that needs to be warmed up. In some cases, two warm-up valves are used for the operation.

4. Requirements for WARM-UP Valves

When selecting a warm-up valve, consider the following characteristics:

- The needle valve design is preferred for throttling steam.

- A ball warm-up valve that can be used in the open position sized to be fully open will allow the system to warm up gradually or a globe valve design.

- The internal permissible leak rate standard should be higher than a Class IV shutoff per FCI or API.

- American National Standards Institute (ANSI) or FCI standards

- API standards

- The outlet piping or tubing needs to be increased by one pipe diameter.

- Example: With ¾” inlet piping and a ¾” warm-up valve, the outlet piping/tubing should be 1” or larger. This will reduce the velocities out of the valve and improve the valve’s reliability.

- Two valves should be installed on the warm-up line:

- One valve for the warm-up operation, and

- A second valve for isolation.

- Double block valve with a bleed valve

- More than one warm-up valve station can be installed

- For larger steam systems

5. Applications for Warm-up Valves

5.1. Steam Isolation Valves

One of the most common applications for warm-up valves is the steam line isolation valve installation.

5.2. Single-Stage PRV Stations

The single-stage PRV is another application for warm-up valves.

5.3. Two-Stage PRV Stations

The two-stage PRV is an additional application for warm-up valves.