Virtual Steam System Engineering

Support Program

Steam and Condensate System Virtual Engineering Support

Virtual Engineering Support

Virtual Steam System Engineering Support is Inveno Engineering, LLC’s latest offering to support our clients during the COVID-19 pandemic and beyond. Access to plant operations can be limited because of the pandemic as well as for a variety of other reasons. The need for engineering support, however, does not change. We have developed the following program to meet the plant needs.

Here’s how it works:

Plant provides information on the current issue or problem with your steam system. The submittal can be in the following areas:

- Safety

- Reliability

- Operations

- Performance

- Energy

- Problem Analysis and Solutions

Our engineers review the problem. If more information is required, our engineers will respond to you by teleconference or email.

Reviews are encompassing with:

- Identification

- Documentation

- Benchmarking

- Our steam system engineering team will be using the latest engineering tools to assist in the virtual diagnosis and analysis

Test equipment can even be provided to the facility for any necessary testing (if required), with training and support.

After our engineers have concluded the investigation, the engineering team will develop and provide the following:

- Video presentation outlining investigation and the roadmap for remediating the problem.

- Written narrative on the video presentation

- Typically, a conference call within a week to follow-up on the root cause analysis study.

Rotating Dryer Inconsistent Temperatures

Rotating Dryer is not achieving a constant surface temperature

Loss of production and product rejects

Root cause analysis investigation

- Original design and operation

- Current operation, installation, operation and safety compliance

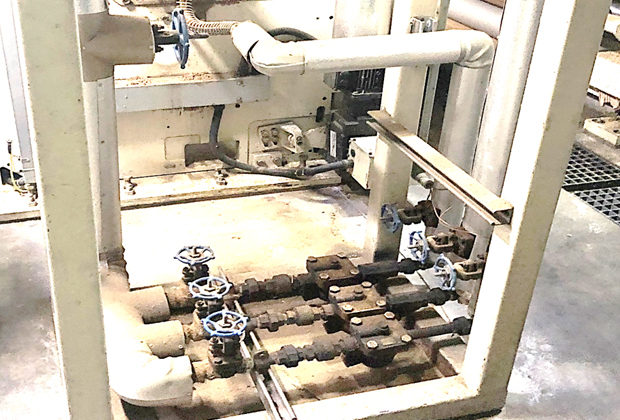

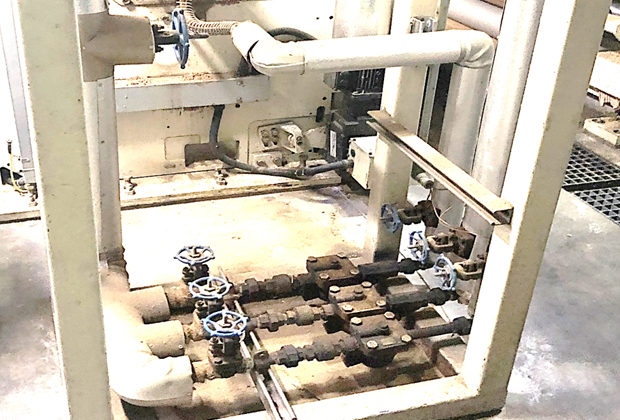

Overview of Current Operation and Components

Item No. 1:

need to install a functional pressure gauge on the steam supply to document proper steam pressure to the dryer

Item No. 2:

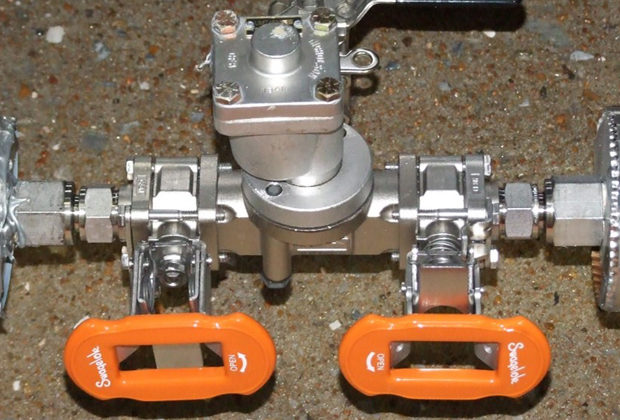

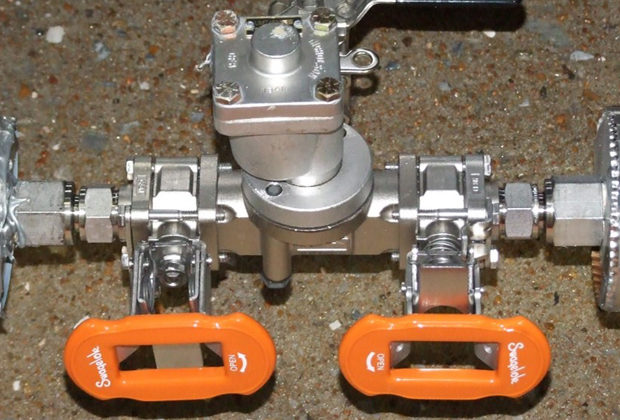

ball valve is not rated for the pressure and temperatures

Item No. 3; Review of the steam hoses:

- Inlet and outlet steam hoses

- Internal diameter is restricting flow

- Reduced diameter off the dryer joint connection

- Hose does not meet B31.1 code requirements

- Outlet steam hose needs to be vertical down at least 20” to assist in drainage

Item No. 4; Review of the steam trap station:

- Strainer

- Isolation valves

- Steam trap design

- Steam trap orifice

- Threaded connections

- Check valve

- Pressure gauge discharge

Short Term Correction Roadmap

Short term:

Replace steam hoses that are correctly sized and code compliant Correct the steam trap orifice to the achieve maximum condensate capacity (see other technical data sheets attached to this email) Isolation valves need to removed and replaced with code compliant valves.

Short term:

Install proper pressure gauges for verifying steam and condensate system pressures Install ball valve on existing strainer and have PM blow downs of the strainer Remove check valve – not need in this application

Long term:

- Install ball valves for isolation

- Design and standardized on a proper steam trap station

- Properly sized

- Eliminate thread connections

Inveno Engineering, LLC’s Technical Papers

Installation Guidelines for Heat Transfer Components

Review all our Best Practices at

We continue to update and add to our library content