Steam Warmup Valves are Critical for Ensuring Steam System Safety

Today’s discussion is the importance of a steam system warm-up valve, which is critical to ensure steam system safety.

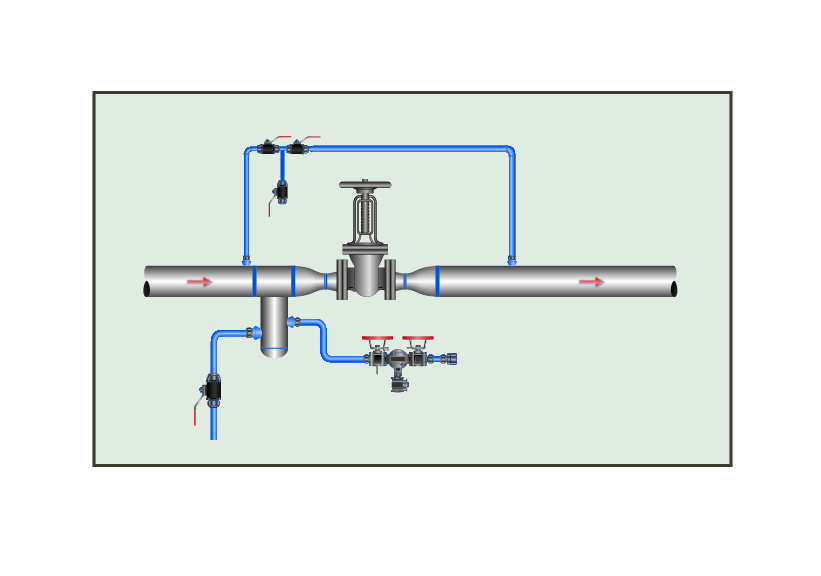

Steam system warm-up valve is an essential part of the steam system. For the initial start-up or warm-up of the steam system, the highest condensation rate will occur or liquid condensate. Also, the maximum thermal expansion of the steam line will occur at start-up. Therefore, we need to have a warm-up valve assembly as shown here in the diagram.

The lack of a proper steam system warm-up valve has negative effects on the system. Safety issues, water hammer, steam line erosion, and premature failures. Without a steam system warm-up valve installed around the main steam isolation valve, personnel may resort to using external force—such as a cheater bar, as shown in the illustration. This is a highly unsafe practice that has led to serious injuries and even fatalities

Why do people have to use external force on a valve? Most people are using older technology for isolation valves. Common isolation valve is a gate valve design, which you have forces, high pressure against the valve gate assembly, which pushes this valve gate up against the valve seating surface because of low steam pressure downstream. Because of this high-pressure, low-pressure difference, to get this valve to come off its seat you will have to use force. But using a warm-up valve around the main insolation valve will allow pressure to equalize from downstream to upstream pressures. Therefore, the valve gate will come in the neutral position, and you will be able to open the valve without any issue.

Using any force on an isolation valve is a very unsafe practice. The valve bonnet is not rated for external force on the steam valve. Using external force, you can damage or even break the bonnet and allow steam to be released to atmosphere, which is an extremely dangerous situation. There are vendors out there selling cheater bars or mechanisms for putting force onto steam valves. This is not acceptable.

Always make sure you equalize the steam pressure around the main isolation valve and then you will not need to use external force.

There are valve manufacturer’s that make valves with built-in warm-up valve assembly. This is not new, it’s been around for a long time.

Remember, any valve that’s three-inch or a larger install a smaller, half, three-quarter, one inch valve around the main isolation valve. The size of the warmup valve will depend on the length and diameter of the steam line.

Predetermined time warm-up for the steam system. Rule-of-thumb is 1 psi per minute or longer. Slow ramp-up time for the desired temperature or pressure is critical. Let the system warm up slowly. There should be no movement in the steam line, no noise and definitely no waterhammer.

Areas that need a warm-up valve are isolation valves that are three-inch and larger, pressure-reducing valve stations or PRV stations, and a few process applications. As you can see, the warm-up valves are located right here and that will allow you to warm up the steam system slowly.

Question on what happens on Monday. Inveno Engineering LLC steam system engineering experts worldwide, we’re here to help you out. On our website there are 82 technical papers and 32 videos, like this here, and also other reference material which is generic. So, if you have questions regarding steam or condensate system, please contact us.

Thankyou and have a great day.

Steam system warm-up valve is an essential part of the steam system. For the initial start-up or warm-up of the steam system, the highest condensation rate will occur or liquid condensate. Also, the maximum thermal expansion of the steam line will occur at start-up. Therefore, we need to have a warm-up valve assembly as shown here in the diagram.

The lack of a proper steam system warm-up valve has negative effects on the system. Safety issues, water hammer, steam line erosion, and premature failures. Without a steam system warm-up valve installed around the main steam isolation valve, personnel may resort to using external force—such as a cheater bar, as shown in the illustration. This is a highly unsafe practice that has led to serious injuries and even fatalities

Why do people have to use external force on a valve? Most people are using older technology for isolation valves. Common isolation valve is a gate valve design, which you have forces, high pressure against the valve gate assembly, which pushes this valve gate up against the valve seating surface because of low steam pressure downstream. Because of this high-pressure, low-pressure difference, to get this valve to come off its seat you will have to use force. But using a warm-up valve around the main insolation valve will allow pressure to equalize from downstream to upstream pressures. Therefore, the valve gate will come in the neutral position, and you will be able to open the valve without any issue.

Using any force on an isolation valve is a very unsafe practice. The valve bonnet is not rated for external force on the steam valve. Using external force, you can damage or even break the bonnet and allow steam to be released to atmosphere, which is an extremely dangerous situation. There are vendors out there selling cheater bars or mechanisms for putting force onto steam valves. This is not acceptable.

Always make sure you equalize the steam pressure around the main isolation valve and then you will not need to use external force.

There are valve manufacturer’s that make valves with built-in warm-up valve assembly. This is not new, it’s been around for a long time.

Remember, any valve that’s three-inch or a larger install a smaller, half, three-quarter, one inch valve around the main isolation valve. The size of the warmup valve will depend on the length and diameter of the steam line.

Predetermined time warm-up for the steam system. Rule-of-thumb is 1 psi per minute or longer. Slow ramp-up time for the desired temperature or pressure is critical. Let the system warm up slowly. There should be no movement in the steam line, no noise and definitely no waterhammer.

Areas that need a warm-up valve are isolation valves that are three-inch and larger, pressure-reducing valve stations or PRV stations, and a few process applications. As you can see, the warm-up valves are located right here and that will allow you to warm up the steam system slowly.

Question on what happens on Monday. Inveno Engineering LLC steam system engineering experts worldwide, we’re here to help you out. On our website there are 82 technical papers and 32 videos, like this here, and also other reference material which is generic. So, if you have questions regarding steam or condensate system, please contact us.

Thankyou and have a great day.