[embed]https://youtu.be/IHMS37C4PwE[/embed]

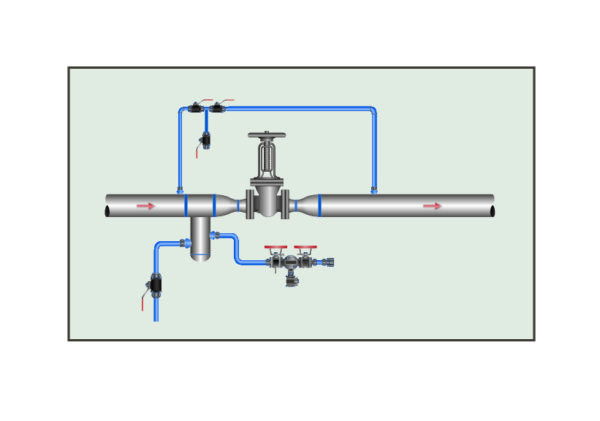

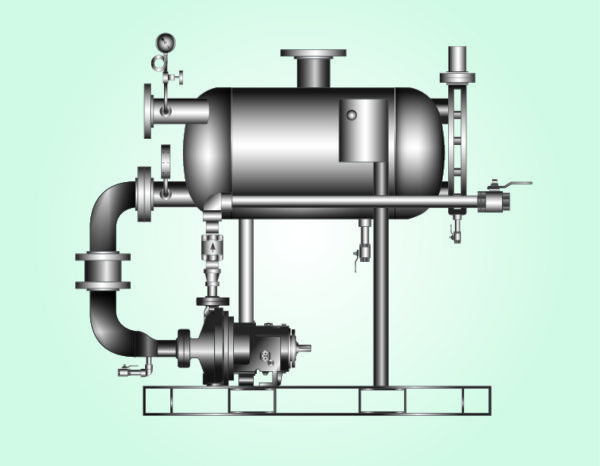

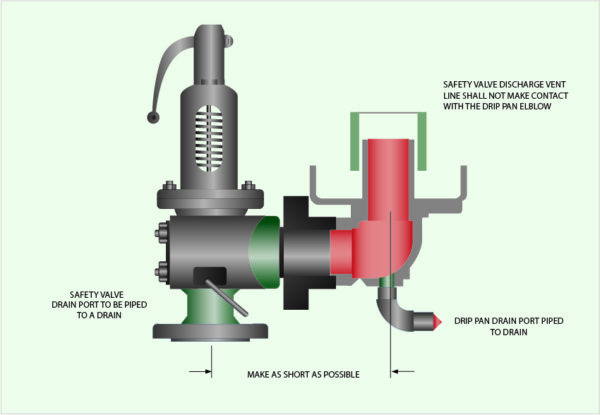

Inveno Engineering LLC, we're global leaders in steam system engineering, recognized for our unmatched steam system expertise and dedication. Today, we would like to review steam line condensate removal, which