Combustion Flame Visual Inspection

Combustion flame visual inspection by Kelly Paffel technical manager Inveno Engineering, LLC

Tampa, Florida, USA

My name is Kelly Paffel. I’m with Inveno Engineering LLC located in Tampa, Florida and today I would like to talk about combustion flame visual inspection. Combustion flame visual inspection, the following presentation is an overview of a combustion flame analysis for plant personnel for the inspection of combustion flame for performance. Remember combustion testing and adjustments should always be done with the use of a combustion analyzer by a certified person. However, a daily visual inspection provides an insight into the combustion performance. Now this can be done by the boiler plant personnel.

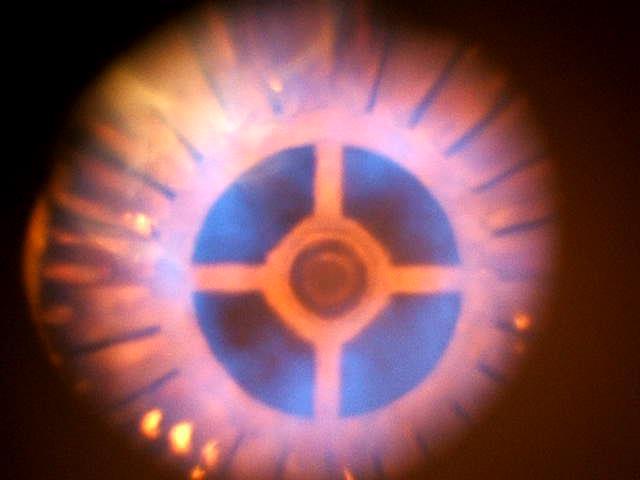

Has a bright yellow color, indicating a high temperature that is distributed throughout the burner throat.

There should be no dark spots in the burner throat. The flame front is in the correct position. Therefore, we are looking for a bright yellow color throughout this burner area. The flame has a swirl to the operation which is mixing the fuel with the air. The end result of this process is low excess air, no carbon monoxide and higher boiler efficiency. Imperfect flame, the throat does not have a red/orange glow or the high temperature. The flame temperature here is about 2800 degrees. With this high temperature, the burner throat should be that red/orange color and the flame front being too far away from the burner throat. If the flame front is too far away, the radiation or heat does not get to the burner throat which does not heat it up evenly. Remember one thing, the burner throat here and here helps the combustion process by providing the temperature to support the combustion process.

Remember three things you need in the combustion process, oxygen, fuel and temperature. And the burner throat helps support that temperature. The burner deficiency results in high levels of carbon monoxide or high levels of excess air. This is just showing another deficiency of the combustion flame. The burner throat area has areas of red and orange coloration but does not completely cover the entire throat area. The result was from poor air flow distribution to the burner, resulting in high levels of carbon monoxide. As you can see, these are areas where it is heated and areas of poor air flow distribution. As the previous slide, the burner is displaying several negative features. The flame front is too far away from the burner throat, air flow mixture is not achieving proper mixture, high levels of carbon monoxide and high levels of excess air.

Also, there is deficiencies in the burner throughout tile and it was not uniform. So you can see the dark areas and these are the areas here where we are getting the temperature into the throat area. Proper combustion flame operation, the throat is totally red and orange in color as you can see up in here, down here and all over here. Results in proper air and fuel mixing, the flame front is in the correct position, resulting in low excess air levels and no carbon monoxide in the process. Another proper combustion process, the burner throat is red/orange hot which means the flame front is in the correct position, the swirl operation to achieve proper air fuel mixture. The front view is more difficult to see the total operation. You can see the flame and the flame geometry but you can’t really see the throat, burner throat performance.

Therefore, we should always be looking at the back wall area forward to the burner. Another key factor is the visual inspection ports and the back of the boiler should always be kept clean, so allowing the boiler plant personnel to achieve visual inspection. Proper combustion efficiency. Visual inspection is a key factor to overall boiler efficiency. Visual inspection is only one piece of checking the combustion efficiency. Full testing should be performed at least every three months by a qualified person. A person coming in and testing for combustion process does not cost you money, it saves you money. Our approach, we are part of your team. Short term impact, we do boiler deep dive analysis, optimization engineering, reliability, steam balancing and training to make sure that you overall achieve the highest steam thermal cycle efficiency.

Long term we are working on upgrades, process changes and adding new technology. Thank you for your time and have a great day.