Combustion Efficiency: Fuel-Air Ratio, Best Practice No. 8

Do you want this article in PDF format? Download it here:

Download a PDFBEST PRACTICE NO. 8, COMBUSTION EFFICIENCY – FUEL AIR RATIO

Achieving Fuel Cost Savings of 1.75% or More

Combustion efficiency is an overlooked area for improving a steam system’s overall thermal cycle efficiency. Deficiencies in combustion efficiency are found on all types of boilers, so having a proactive combustion testing program, conducted either in house or by an outside contractor, can help plants achieve a substantial gain in efficiency.

Inveno’s analysis of steam system engineering assessments shows that a high percentage of boilers are operating with low combustion efficiency and not operating at peak performance. Reducing excess air increases flame temperatures in the combustion furnace chamber and reduces stack temperature, thus increasing combustion efficiency and overall boiler efficiency. A widely used rule of thumb for estimating energy savings is that for every 40°F reduction in stack temperature, there will be a corresponding 1% increase in boiler efficiency.

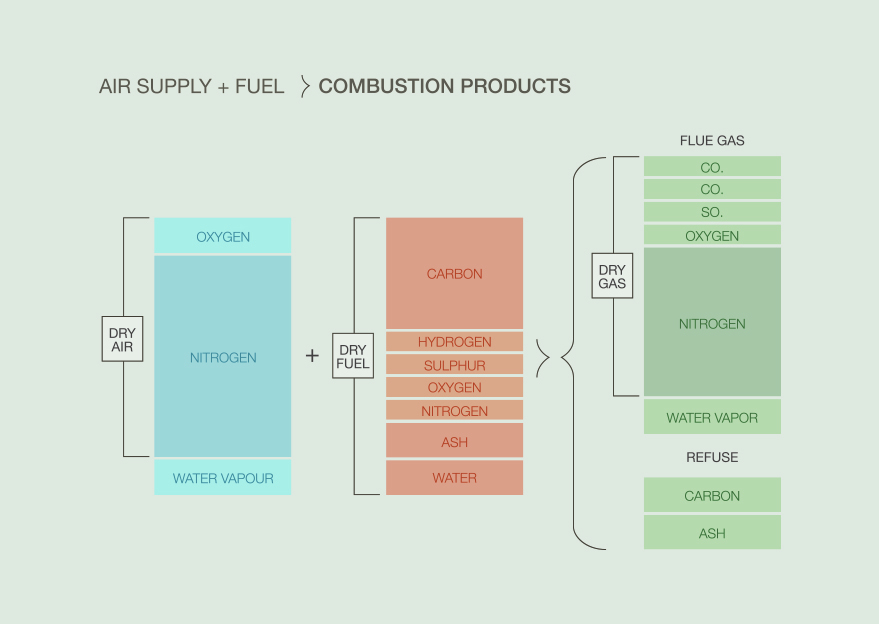

Figure 1. Example of a Fuel-Air Ratio

What Is the Combustion Efficiency or a Fuel-Air Ratio?

The fuel-air ratio curve is the lowest excess air level (measured in percent of oxygen (O2)) in the flue gas at a set firing rate without carbon monoxide (CO) being produced. At lower firing rates, the burner design requires more excess air to ensure the air mixes with the fuel. At higher firing rates, there is enough differential pressure drop (burner windbox to combustion chamber area) for air to mix with the fuel.

All boilers have a fuel-air ratio curve, and it is extremely important that plants have this documented information.

To increase boiler efficiency, Inveno recommends that plants conduct periodic testing and adjustments to the boiler burners at least twice a year. A common and undesirable practice is to test and adjust at two points only, a high- and low-firing rate, but this usually results in inefficient combustion at intermediate rates. The best practice is to adjust the burner at 10 or more different points along the fuel-air ratio curve.

What Are the Parameters?

The flue gas analysis should include oxygen in percentages and carbon monoxide in ppm (not percentages). The intent is to have the lowest percentage of oxygen, with a carbon monoxide (CO) reading of less than 250 ppm.

What Are the Measurements?

Combustion analyzers are available that can determine the amount of excess air in combustion by measuring the contents of flue gases. The U.S. Department of Energy and Inveno Engineering recommend such an investment for boiler systems with annual fuel costs above $50,000.

Equipment that measures oxygen is more precise than carbon dioxide measuring devices. The other crucial measurement is carbon monoxide (CO) measured in ppm (parts per million). Information from the combustion analysis equipment is used to calibrate the settings on the air and fuel supply systems for the combustion process.

Figure 2. Combustion Process

In steam operating boilers, excess air should be targeted to achieve approximately 10% (2.2% oxygen). This will vary from boiler/burner to boiler/burner and from application to application; always consult the burner manufacturer’s manual or the original startup data.

Who Is Qualified to Set the Fuel-Air Ratio Curve?

Contact the burner manufacturer for safety procedures and instructions before making adjustments, and always adhere to applicable codes. If the plant has qualified personnel, it is usually done in-house. If not, plants will have an outside vendor supply these services. If you are using an outside service, you must make sure the contractor is qualified. In 62% of our combustion efficiency assessments, outside contractors are not doing the combustion testing correctly or are not qualified to work on the burner.

Inveno Engineering has found that, on average, a qualified combustion vendor will save a plant more than 2.34% in fuel costs.

What Information Is Required?

At the end of this Best Practice is a combustion data sheet required to be completed during the testing process. The combustion data is extremely important in benchmarking the combustion process.

How to Find a Qualified Combustion Testing Contractor

A combustion contractor must have experience with the boiler/burner combination that the plant has in operation. Some contractors do a great job with fire-tube boiler/burner design systems but have very little experience with water-tube boiler/burner combination systems.

FAQ

Question:

If I have a contractor perform combustion testing on the boilers, how do I know whether it is doing the testing correctly?

Answer:

This is usually easy to find out. The original startup boiler/burner manual should include all startup data and the combustion curve. It will be in a printed form typically called the combustion testing report. If the report is not in the manual, call the boiler/burner manufacturer to obtain the data.

Figure 3: Natural Gas/fuel oil Burner

The U.S. Department of Energy Steam Best Practices Committee has an excellent tip sheet on combustion efficiency. Download the tip sheet and other information at Inveno’s Resource Library page or e-mail kelly.paffel@invenoinc.com for a copy.about:blan

Best Practices:

- Benchmark the proper fuel-air ratio curve.

- Check combustion every three months.