No. 55 – Eliminate Unwanted Steam Venting

Do you want this article in PDF format? Download it here:

Download a PDFBest Practice No. 55

How to Eliminate Steam Venting and Stop the Major Energy Loss

1. OVERVIEW

With today’s competitive international market, all plants need to reduce operating costs, and lowering energy consumption can have a positive impact on the bottom line. A plant’s steam and condensate systems cannot afford to vent any utility steam, blowthrough steam, or flash steam to the atmosphere. An additional benefit of not venting steam is a significant reduction in emissions in the boiler operation.

Any steam venting from the steam and condensate system is the top reason for lost energy in today’s steam systems. Can this objective be accomplished? The following technical paper will review the methods to eliminate steam venting and achieve a high steam system thermal cycle efficiency.

1.1 how to eliminate steam venting

There are two types of steam systems in plant operations today.

| Figure 1. Flash Steam Vent Condensate |

Modulating Steam System

A modulating steam/condensate process means the process application has a steam control valve that modulates the steam to the process. The steam control valve can operate from 0% (closed) to 100% (fully open) and anywhere in between.

The modulating steam system’s operational design requires the condensate from the processes to be recovered by a gravity (0 psig) condensate system.

The condensate system will incorporate a condensate receiver that allows the flash steam to vent to the atmosphere. The venting of the flash steam ensures the condensate receiver is never pressurized.

To prevent the flash steam loss to the atmosphere, plants install devices such as flash steam vent condensers in the flash steam vent line.

| Figure 2. Steam Vent: Air Condenser Design |

A flash steam vent condenser is incorporated in the system to recover the flash steam by using an external heat exchanger (condenser).

The vent condenser (heat exchanger) will consume the flash steam by heating air, water, or some other process fluids. The vent condenser is designed for the application to ensure proper operation.

The process fluid consumes the flash steam and allows the condensate to drain back into the condensate tank. Therefore, the flash steam is consumed, and the condensate is recovered.

All vented condensers are engineered for the application.

1.2 Nonmodulating Steam Systems

A nonmodulating steam condition means there is no control valve modulating steam flow to the process. If there is a steam control valve, it always maintains a steam pressure to the process that is higher than the pressure in the condensate recovery system. This system is classified as a nonmodulating steam process.

A nonmodulating process steam system provides a steam pressure to the process that will provide a differential pressure on the drain device (steam control valve or steam trap station).

Examples of nonmodulating steam processes include the following:

- steam tracing,

- processes with temperatures above 240°F,

- drip leg steam traps,

- process heaters,

- reboilers,

- corrugators, and

The typical plant operation is not designed to accommodate the higher condensate temperatures and additional flash steam generated by the nonmodulating steam system. In these operations, the condensate and flash steam are delivered to a vented condensate tank system. The flash steam is then vented to the atmosphere, and a substantial energy loss occurs.

However, flash steam can be recovered by using a cascade system that incorporates a flash tank system or by using a thermocompressor system.

| Figure 3 Flash Tank System |

The two-phase flow (flash/condensate) from the process discharge can be directed to the pressurized flash tank for separation. The flash steam then can be delivered to a lower-pressure steam header system. This method is referred to as a cascading flash steam system.

1.4 Thermocompressing

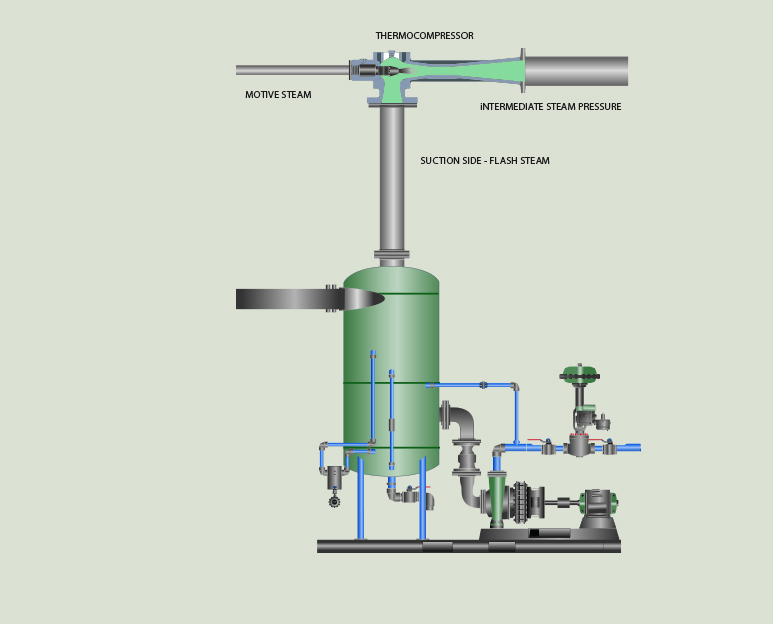

| Figure 4. Flash Steam Recovery With a Thermocompressor System |

A large number of plants do not have a need for low-pressure steam; therefore, the cascade steam system is not a benefit. Another method to recover the flash steam is to use a thermocompressing system. Thermocompressing takes the low-pressure steam and produces a higher, usable steam pressure.

The thermocompressor is a simple device that has existed for many years. It has a nozzle where high-pressure steam is accelerated into a high-velocity fluid. The high velocity entrains the low-pressure steam from the flash tank by momentum transfer and then recompresses it in a divergent venturi. The result is an intermediate steam pressure that is useful to the plant operation.

1.5 Process Outlet Temperatures Above 240°F

There are processes where the outlet temperatures are at or above 240°F, which means the steam control valve will never reduce the steam pressure below the steam pressure equal to the process temperature.

Example:

- Process outlet temperature: 310°F

- Steam pressure @ 310°F: 90 psig

The steam pressure will not be lower than 90 psig; therefore, the condensate can be discharged into a flash tank, and the flash can be used in a cascade system or thermocompressing system.

2. Conclusion

Tomorrow would be a good day to start following the road map to prevent any steam from venting to the atmosphere.

| Figure 5. Plant Operation: No Steam Venting |