No. 51 – Pressurized Condensate Recovery

Do you want this article in PDF format? Download it here:

Download a PDFBEST PRACTICE NO. 51

Pressurized Condensate Recovery

READ FULL PDF TECHNICAL PAPER – CLICK HERE

Pressurized condensate systems can provide plants with a minimum of between 15% and 35% savings in fuel costs when compared to a conventional atmospherically vented condensate system. That is a tremendous opportunity for facilities, since fuel prices have gone up and are expected to increase even further. The pressurized condensate system is not a luxury; rather, it is a necessary component to maximize and increase the steam system’s efficiency. Unfortunately, not all steam plants or steam applications can implement a high-pressure condensate return system.

Figure 1: New Pressurized Condensate Tank System

Therefore, proper preliminary engineering assessment, design review, and knowledge of the application are necessary to ensure a successful condensate system. In the examples that are included in the technical paper, we achieved an energy savings of $ 226,700.00 by implementing a 50 psig pressurized condensate system.

The project was implemented at a cost of $305,400.00, yielding a 1.3-year payback.

1. What is a Pressurized Condensate System?

Pressurized condensate recovery systems operate continuously at a pressure above 15 psig, and the condensate recovery system is not vented to the atmosphere. The pressure in the condensate system is sustained by the dynamics of the system or a systematic control process loop. Typical condensate systems operate with backpressure because their condensate line is improperly sized for two-phase flow and because plants neglect steam trap stations blowing steam into the condensate line. These items alone can cause unwanted and uncontrollable pressure in the condensate recovery system. A pressurized condensate recovery system differs in that the condensate return line pressure is systematically controlled and managed to a predetermined set point that matches the peak performance level of the steam system process and integrates into the dynamics of the steam balance.

Four classifications of condensate systems are used in plants today:

- gravity or atmospheric (condensate line pressure maintained at or close to 0 psig),

- low pressure (1 to 15 psig),

- medium pressure (16 to 99 psig), and

- high pressure (100 psig or higher).

Pressurized condensate system technology is not new in the steam world; these systems can be documented back to 1941. Though the technology may be considered old, it has been overlooked over the years due to relatively inexpensive fuel prices. As fuel prices have risen and, with them, the need for optimization to reduce overall operational costs, industrial plants are paying more attention to these systems, because they have proven to be a significant way to decrease expenses. Pressurized condensate systems are considered one of the top three items to optimize a steam system with a very attractive payback for the investment.

Here is an example of an atmospheric system.

Figure 2: Atmospheric Condensate System

2. Why Maintain a Pressurized Condensate System? TO Increase Efficiency AND Reduce Energy Costs

The best reason to use a pressurized condensate system is the remarkable energy savings that plants can often achieve with a low implementation cost. Any condensate that is not contaminated in a process application needs to be returned to the boiler operation to complete and increase the steam system’s thermal cycle. Condensate contains a high quantity of sensible energy. If the sensible energy is not properly returned to the boiler operation, a large percentage, if not all, of this energy is lost.

Condensate that is returned to the boiler operation will require the condensate temperature to be raised to the saturated temperature of the steam boiler’s operating pressure. To accomplish this task, energy is introduced at the deaerator and the boiler. The deaerator will add energy to heat the condensate to a temperature where noncondensable gases will be removed from the fluid. The boiler will add the energy for phase change to occur at the boiler operating pressure.

The higher the temperature or pressure (direct relationship in steam) of the condensate being returned to the boiler plant, the less energy that is required to raise the temperature of the condensate back to the saturated temperature of the boiler operating pressure.

The most efficient system is a condensate return system controlled at a pressure as close to the boiler operating pressure as possible. In a perfect system, the steam system would operate at 150 psi, and the pressurized condensate system would operate at 149 psi. However, the limitation is the type of steam and condensate system: the plant must consider elements such as line sizes, distances, steam trap station differential, and elevations. With these variables in the system, a typical target for pressure differential between the steam supply and condensate return is between 30% and 45%. All pressurized condensate systems must be thoroughly evaluated before selecting the condensate return line pressure.

3. WHAT ARE THE SAVINGS?

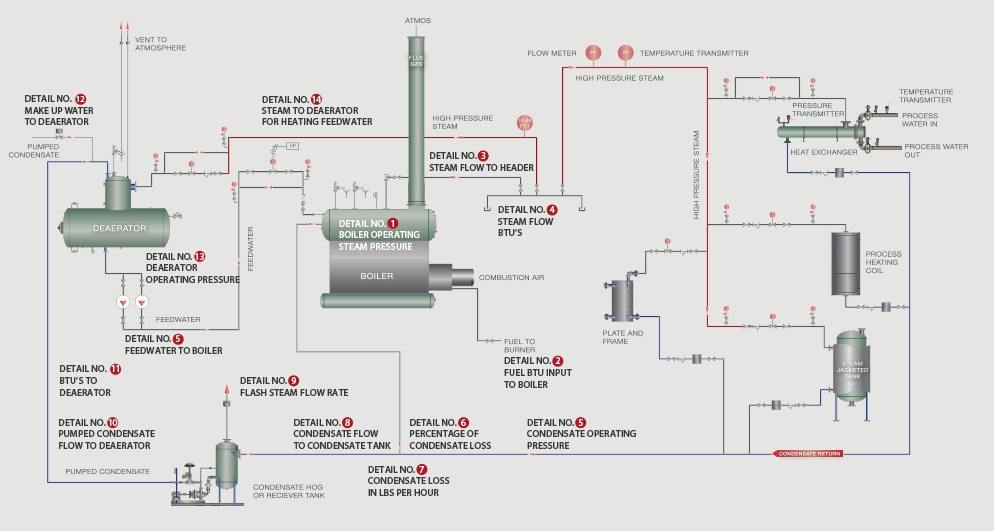

To determine the cost savings of a standard condensate system vs. a pressurized condensate system, it is important to review all operational parameters. Review the following prints and detailed printouts of the steam and condensate system:

- Detail 1: Boiler operating steam pressure

- Detail 2: Fuel input into the boiler (Btus)

- Detail 3: Steam flow output from the boiler (Btus)

- Detail 4: Steam flow Btus

- Detail 5: Condensate system operating pressure

- Detail 6: Percentage of condensate loss

- Detail 7: Condensate loss (lbs./hr.)

- Detail 8: Condensate flow to condensate tank (lbs./hr.)

- Detail 9: Flash steam flow rate (lbs./hr.)

- Detail 10: Pumped condensate flow to deaerator

- Detail 11: Condensate Btu’s to Deaerator

- Detail 12: Make-Up Water Flow Rate to Deaerator

- Detail 13: Deaerator Operating Pressure

- Detail 14: Steam Flow to Deaerator for Heating

Feedwater

Figure 3: Condensate System With All Location Details

3.1. Standard Condensate Return System

A standard condensate system, where condensate is recovered into an atmospheric condensate tank system, will have inherent energy losses. These energy losses are as follows:

- condensate is allowed to cool to 212°F,

- a large amount of flash steam is generated,

- flash steam is allowed to escape to the atmosphere, and

- flash steam losses increase the quantity of make-up water.

All condensate and make-up water, which will become boiler feedwater, will require energy input to bring the energy level up to the saturated temperature of the boiler operating pressure. Reducing the differential energy levels (condensate and make-up water) to the boiler saturated energy level will increase the steam system’s thermal cycle efficiency.

4. TYPICAL DETAILS OF ONE STEAM APPLICATION IN A PROCESS PLANT

Application:

Steam process

Steam pressure supplied to the process:

150 psi (before a control valve) equivalent

Steam temperature:

366°F

Steam pressure at the process:

150 psi pressure)

Steam flow rate:

24,000 lbs./hr. (minimum)

Operation:

8,760 hrs./yr.

Condensate line pressure:

0 psig (vented to the atmosphere and mechanically pumped back to the boiler plant)

Cost of steam (per thousand lbs.):

$5.24

5. EXAMPLE 1: STEAM PROCESS CONDITIONS

A steam requirement for the process applications is rated at 24,000 lbs. per hour, which provides 24,000 lbs. per hour of condensate. Condensate is drained from the steam process through a standard steam trap station. The steam trap station discharges condensate into a vented condensate receiver system. When condensate is drained from the process at a given pressure (150 psi) and passes through a steam trap station to a lower pressure (0 psi @ 212°F), then a percentage of the condensate will flash to steam. The vented condensate receiver tank allows the flash steam to be vented to the atmosphere and ultimately leads to a loss of energy, and the flash steam loss will increase the quantity of make-up water. The condensate is allowed to be reduced to 212°F, which will require an influx of energy at the deaerator and boiler to achieve phase change at 150 psig. The deaerator will use essential steam (steam off the main header) to heat the low temperature condensate and make-up water up to the operating saturated conditions of the deaerator operating pressure.

6. SUMMARY OF ENERGY LOSSES WITH A TYPICAL VENTED CONDENSATE RETURN SYSTEM

- Summary of Operational Costs:

- Boiler fuel cost (yearly): $1,167,301.00

- Flash steam losses: $162,043.00

- Steam for deaerator operation: $64,657.00

- Total energy loss cost: $226,700.00

The atmospheric system has a total energy loss of $226,700.00 per year as a result of flash steam loss, deaerator steam requirements to heat the low temperature and make-up water, and the cost of additional chemicals.

CONDENSATE SYSTEM CALCULATOR ATMOSPHERIC, LOW, MEDIUM, OR HIGH PRESSURE OPPORTUNITY FOR IMPLEMENTATION

7. PRESSURIZED CONDENSATE SYSTEM

Quantifying the losses in terms of money is the first step to developing an improvement plan. Pressurized condensate systems are an excellent method for reducing these losses by 75% or more, depending on the current operating conditions of the steam and condensate system. Understanding the dynamics of the current system and the dynamics of implementing a pressurized system will lead to a successful implementation.

7.1. Implementing a Pressurized Condensate System

In a pressurized condensate system, typical losses will be greatly reduced or eliminated by the dynamics of the pressurized system. The pressurized system will have several benefits.

- It will increase the condensate temperature or sensible energy level. The condensate temperature in the pressurized system is now at the temperature of the deaerator or higher. Therefore, the deaerator does not require essential steam (energy) to heat the condensate, saving essential steam.

- Another benefit to pressurized condensate is that condensate has not been exposed to the atmosphere and has not absorbed any noncondensable gases. The condensate does not have to go through the deaerator process. In several types of installations, the condensate can be delivered directly into the boiler.

- It will reduce make-up water usage. With the flash steam being recovered in a pressurized system, no flash steam is lost. Thus, the only need for make-up water is to replenish the deaerator’s noncondensable vent losses. The make-up costs are negligible in a pressurized system. Reducing make-up water also will reduce boiler blowdown, thus reducing another energy loss in the boiler operation.

- It will reduce the flash steam quantity that is generated, which will reduce the condensate pipe sizing requirements and reduce the condensate losses (1 lb. of flash steam is 1 lb. of condensate).

- It will reduce the energy differential (condensate vs boiler operating condition. This will reduce the amount of fuel input into the boiler to raise the feedwater to the appropriate phase change temperature.

- It will enable the plant to use the flash steam from a pressurized system.

Before changing everything to a pressurized condensate system, the first step is to ensure that the steam/condensate system and the steam processes will be able to operate in the new conditions. Condensate and flash steam (two-phase flow) discharging from a nonmodulating or elevated temperature process can operate in a pressurized condensate system.

- A nonmodulating steam condition refers to a steam system process where no control valve modulates the steam flow into the process to maintain a desired temperature or pressure. A process steam system that lacks a modulating steam control scheme for the process provides a constant steam pressure to the process. Therefore, if the condensate recovery system has a controlled pressure, there is a constant pressure differential across the steam trap stations or condensate discharge control valve.

- In a high-temperature process where the process temperature is higher than the pressurized condensate system, there will be differential pressure across the drain devices, such as the steam trap station or condensate discharge control valve.

Figure 4: High Temperature Process Outlet Temperature of 320°F

Example: If the process temperature is at 320°F, steam pressure to the process has to be higher than 75 psig. With steam pressure of 75 psig to the heat exchanger, P4 (in the example) will have a pressure of 70 psig or greater, and the condensate line pressure could operate at 30 psig.

Here are some examples of steam systems and processes:

- steam tracing

- process ovens

- process heating systems

- steam line condensate removal steam trap stations

- paper machines

- rubber processes

- press operations

- reboilers

- corrugators

- etc.

8. SUMMARY OF THE ENERGY SAVINGS BY IMPLEMENTING A PRESSURIZED CONDENSATE SYSTEM

Using the same example of an atmospheric condensate system and implementing a pressurized condensate system (increase the condensate pressure to 50 psig), the optimization results are as follows:

- Boiler fuel cost (yearly): $1,167,301.00 vs. $940,601.00

- Flash steam losses: $162,043.00 vs. $0.00

- Steam for deaerator operation: $64,657.00 vs. $0.00

Implementation of a condensate system that is operating at 50 psig instead of 0 psig resulted in a savings of $226,700.00.

CONDENSATE SYSTEM CALCULATOR ATMOSPHERIC, LOW, MEDIUM, OR HIGH PRESSURE OPPORTUNITY FOR IMPLEMENTATION

Figure 5: New Pressurized Condensate System

- Condensate line now operates at 50 psig

- Flash is operating at 50 psig with the flash steam going to the deaerator

- Deaerator is operating at 50 psig

- Condensate is directed to the storage side of the deaerator

- Steam system is balanced and the Steam System Thermal Cycle Efficiency is increased

9. COMPONENTS REQUIRED FOR A PRESSURIZED SYSTEM

Several components are required to implement a pressurized condensate system.

9.1. Pressure Control System

A pressure control system controls the condensate pressure to a predetermined set point. The condensate pressure must be managed. One method is to use a backpressure control valve with a controller. An easier method is to use the flash tank discharging into the steam system that has a controlled steam pressure.

9.2. Flash Tank or Deaerator

Installing a flash tank system that delivers flash steam to a controlled steam system is an excellent way to operate the pressurized condensate system. One user of flash steam is the deaerator, which normally operates below 15 psig. Most steam systems have several operating steam pressures, so the flash steam can accept the cascaded steam.

Another method uses a thermocompressor to raise the flash steam’s pressure and reintroduce it into the steam processes or deliver the steam into a plant steam system pressure distribution system. Installing a new deaerator or using the current deaerator, which can operate at a higher pressure, is a third method of receiving the pressurized condensate. The deaerator is operated at a predetermined operating pressure that is the same as the pressure in the pressurized condensate system. The condensate temperature is already elevated, and there will be a reduced quantity of flash steam, which is normally consumed by heating the make-up water.

9.3. Pressurized Condensate

Pressurized condensate does not have to be deaerated and can be pumped directly back into the boiler. The condensate has not been exposed to the atmosphere; therefore, it has not obtained any noncondensable gases.

9.4. Condensate Line Sizing

Condensate line sizing always needs to be checked to ensure it has the proper design to operate in a pressurized operation. Typically, the condensate line size required is reduced by the lower quantity of flash steam, which normally requires more area in atmospheric or very low operating pressure condensate lines. Velocities are also reduced due to the lower flash steam quantity, thus eliminating the normal water hammer issues with high condensate line velocities.

10. HOW TO GET STARTED

There are many reasons to implement a pressurized condensate system and no reason not to implement one. The first step is for plant personnel or an outside firm experienced in pressurized condensate systems to conduct a steam and condensate assessment. The assessment will provide the knowledge of the benefits of pressurized condensate system and, more importantly, the cost of implementation.