December 8, 2017

No. 48 – Combustion Flame Visual Reviews for Performance

Do you want this article in PDF format? Download it here:

Download a PDFBEST PRACTICE NO. 48

Combustion Flame Visual Inspection

READ FULL PDF TECHNICAL PAPER – CLICK HERE

- The following presentation is an overview of a combustion flame analysis for plant personnel for the inspection of the combustion flame for performance

- The combustion testing and adjustments should always be done with the use of combustion analyzer

- However, a daily visual inspection provides an insight into the combustion performance

What is a Good Flame Geometry

- Burner throat has a bright red/yellow color (indicating a high temperature) that is distributed through out the burner throat

- No dark spots in the burner throat area

- Flame front is in the correct position

A Good Flame Pattern

- The flame has a swirl to the operation which is mixing the fuel with the air

- End Result:

– Low excess air

– No carbon monoxide

– Higher boiler efficiency

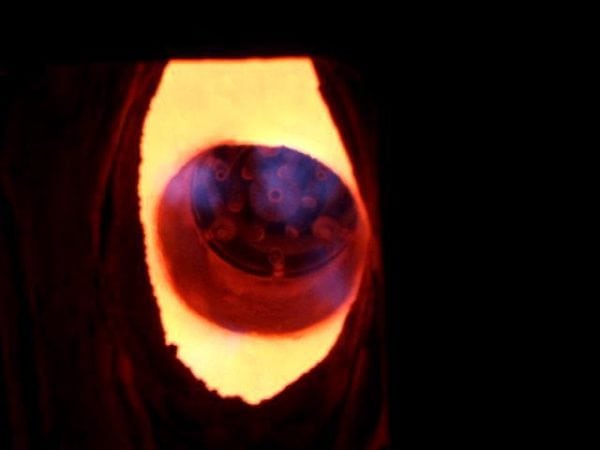

A Imperfect Flame

- The throat does not have a red/orange glow (high temperature) which is an example of the flame front

being too far away from the burner throat - The burner throat helps the combustion process by providing temperature to support the combustion process

Burner Flame Deficiency

- Results in high levels of carbon monoxide

- High levels of excess air Another Deficient Combustion Flame

Another Deficient Combustion Flame

- Burner throat has areas of red/orange, but does not completely cover the entire throat area

- The results was from poor air flow distribution in the burner

- Resulting in high levels of carbon monoxide Another Example of Poor Air Flow Mixture

Another Example of Poor Air Flow Mixture

- Same as the previous slide, the burner is displaying several negative features:

– Flame front to far away from the burner throat area

– Air flow mixture is not achieving proper mixture

– High levels of carbon monoxide

– High levels of excess air

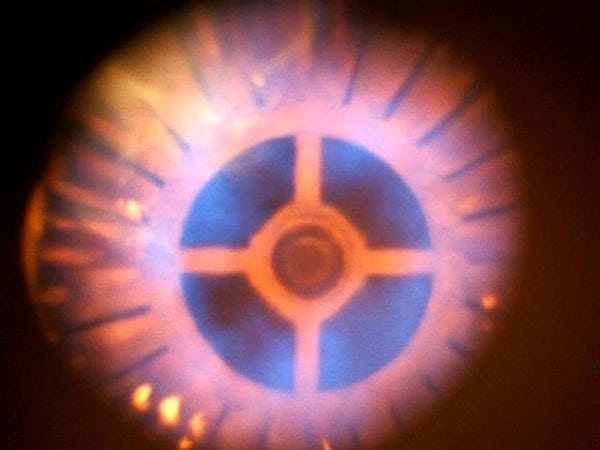

Proper Combustion Flame Operation

- Throat area totally has the red/orange color which is the result of the following:

– Proper air and fuel mixing

– Flame front is in the correct position

– Resulting in the following:

› Low excess air levels

› No carbon monoxide in the combustion process

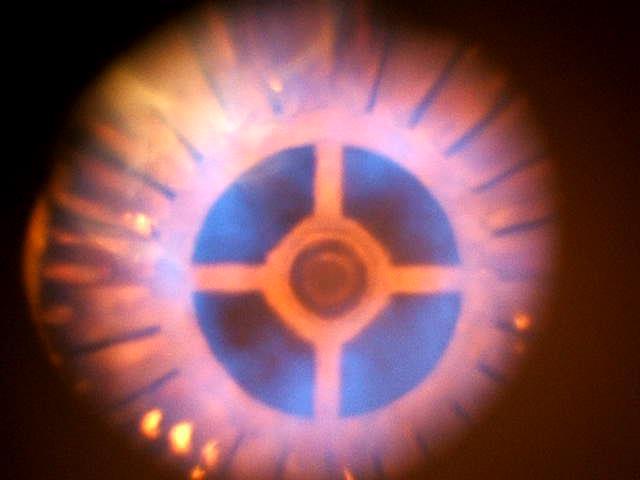

Proper Combustion Operation

- Burner throat is red/orange (hot) which means flame front is in correct position

- Proper swirl operation to achieve air/fuel mixing Another View of the Combustion Flame

Another View of the Combustion Flame

- Front view

– More difficult to see the total operation

Proper Combustion Efficiency

- Visual inspection is a key factor in overall boiler efficiency

- Visual inspection is only one piece of the checking the combustion efficiency

- Full testing should be performed at least every three months by a qualified person