Combustion Flame Inspection and Visual Reviews – Best Practice No. 48

Do you want this article in PDF format? Download it here:

Download a PDFBEST PRACTICE NO. 48

Combustion Flame Visual Inspection

- The following presentation is an overview of a combustion flame analysis for plant personnel for the inspection of the combustion flame for performance

- The combustion testing and adjustments should always be done with the use of combustion analyzer

- However, a daily visual inspection provides an insight into the combustion performance

What is a Good Flame Geometry

- Burner throat has a bright red/yellow color (indicating a high temperature) that is distributed through out the burner throat

- No dark spots in the burner throat area

- Flame front is in the correct position

A Good Flame Pattern

The flame has a swirl to the operation which is mixing the fuel with the air.

End Result:

- Low excess air

- No carbon monoxide

- Higher boiler efficiency

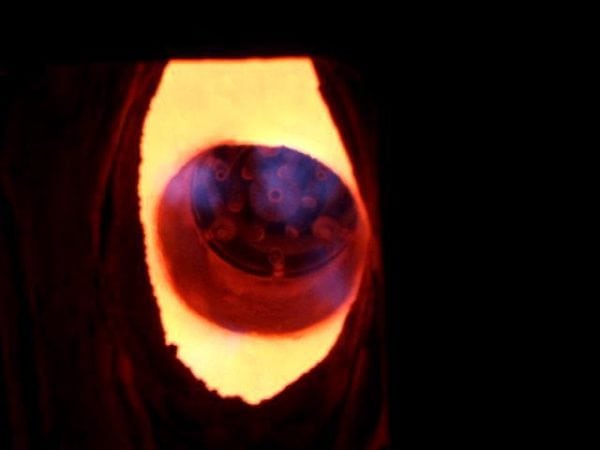

A Imperfect Flame

- The throat does not have a red/orange glow (high temperature) which is an example of the flame front

being too far away from the burner throat - The burner throat helps the combustion process by providing temperature to support the combustion process

Burner Flame Deficiency

- Results in high levels of carbon monoxide

- High levels of excess air Another Deficient Combustion Flame

Another Deficient Combustion Flame

- Burner throat has areas of red/orange, but does not completely cover the entire throat area

- The results was from poor air flow distribution in the burner

- Resulting in high levels of carbon monoxide Another Example of Poor Air Flow Mixture

Another Example of Poor Air Flow Mixture

Same as the previous slide, the burner is displaying several negative features:

- Flame front to far away from the burner throat area

- Air flow mixture is not achieving proper mixture

- High levels of carbon monoxide

- High levels of excess air

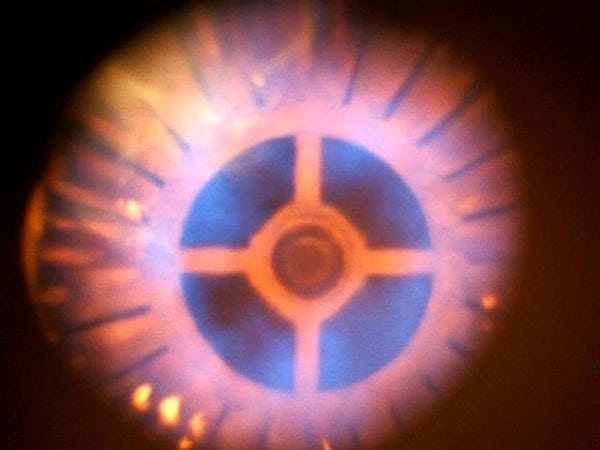

Proper Combustion Flame Operation

Throat area totally has the red/orange color which is the result of the following:

- Proper air and fuel mixing

- Flame front is in the correct position

Resulting in the following:

- Low excess air levels

- No carbon monoxide in the combustion process

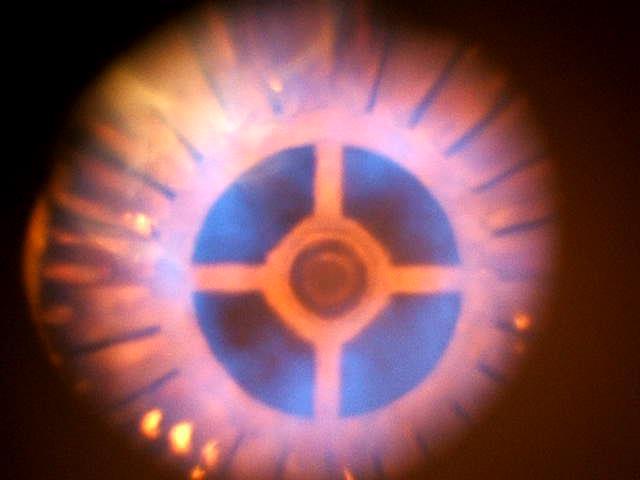

Proper Combustion Operation

- Burner throat is red/orange (hot) which means flame front is in correct position

- Proper swirl operation to achieve air/fuel mixing Another View of the Combustion Flame

Another View of the Combustion Flame

- Front view

– More difficult to see the total operation

Proper Combustion Efficiency

- Visual inspection is a key factor in overall boiler efficiency

- Visual inspection is only one piece of the checking the combustion efficiency

- Full testing should be performed at least every three months by a qualified person