Best Practice No. 14 – Guide Line for Boiler Room Logs

Do you want this article in PDF format? Download it here:

Download a PDFBEST PRACTICE NO. 14

GUIDE FOR BOILER ROOM LOGS

READ FULL PDF TECHNICAL PAPER – CLICK HERE

SCOPE OF BOILER LOGBOOK PROGRAM

In all cases, there are minimum tasks and functions for an operator to perform in a boiler plant that is dependent upon the complexity, size and condition of the equipment. The manager in charge may or may not be a licensed operator but in all cases the rule of thumb to understand is that the entire boiler room is the “realm” of the operator and any anomalies should be reported within the operator’s logbook entry. Management practices and policies should always ensure safety is fully addressed in the operation of the boiler plant. All operators should qualify prior to giving them the responsibility of operating and monitoring such potentially hazardous equipment.

NOTE: It must be understood, the actual operator logbook entry is not just a list of readings, though in some cases readings might be a part of the logbook entry. This depends upon the type or size of the logbook provided by the owners and/or management of the facility. See the example logbook entry section on the last page of this guideline.

- Entries in the logbook should include details of the existing operations (naturally occurring) and indicate all observations that are abnormal or unusual in their occurrence.

- The logbook should report on the mechanical and operating conditions found at the time of observation.

- Rounds in the boiler plant (room) should be a top to bottom, front to rear assessment of the boiler and the controls and safety devices that are an integral part of its functions.

- Plant environment, organizational safety practices or requirements, or management procedure may dictate that more frequent checks be made.

- It is common practice for an operator to put into the logbook all issues and items specific to operating the facility. Therefore, if a low-pressure operator cannot make it back within the designated period established in the regulations, the operator should when possible, have another trained and licensed operator make the check of the boiler plant. If no operator is present, then the licensed operator should take whatever action is necessary to expedite returning to the equipment entrusted to his or her care.

- The operator, upon returning to the boiler room should indicate in the logbook all time away from the boiler plant. The logbook entry should be clear and indicate the reason why a check could not be made and the reason the inspection interval was exceeded. Any work assignments or instruction from management that the operator received specific to the boiler plant should be indicated within the logbook as such, and if an emergency arises, the same would apply by indicating the nature of the emergency and duration of the event.

2. TYPICAL DAILY READINGS TO OBSERVE AND REPORT

Daily Instrument Readings are contained as a part of or indicated on a separate record, depending upon the complexity of the mandatory boiler operator’s logbook.

The following instrument readings, as appropriate to the specific boiler system, need to be taken daily for low-pressure heating boilers and at least once per eight-hour shift for high-pressure boilers or as required by the owner, manager or other responsible party. These readings must be recorded either in the boiler logbook if the arrangement of the logbook accommodates them, otherwise if reading are extensive in nature, a separate logbook of readings must be maintained.

Note: It is very important that the boiler logbook and readings be kept in a consistent format, in order for trends to be perceived and followed with preventive or predictive action. Standard forms are available for this purpose; however, the log may be more useful if the log form is customized for the particular installation by the owner.

The readings report should be on the testing interval as recommended by the manufacturer of the critical safety device or controls. Create a calibration and regular proof test interval for all critical safety devices and components.

GENERAL

- Air compressor, control pressure (psig)

- Outdoor air temperature (degrees F)

- City water supply pressure (psig)

BOILER

- Boiler(s) in service

- Fuel in use

- Operating time (hours)

- Operating cycles (number)

- Amount of fuel on hand

- Amount of fuel consumed

- Boiler water level (normal, low, high)

- Firing level (rate)

- Flame condition (observed)

- Boiler water temperature, hot water (degrees F)

- Stack temperature, net (degrees F)

GAS FUEL

- Pilot gas pressure (inches WC)

- Burner gas pressure (ounces/square inch or psig)

- Gas used (cubic feet)

OIL FUEL

- Oil pump in service

- Oil consumed (gallons)

- Vacuum at oil pump (inches Hg)

- Oil pressure at pump (psig)

- Oil pressure at burner (psig)

- Oil pressure at regulating valve (psig)

- Atomizing medium pressure, air, steam (psig)

CONDENSATE SYSTEM (steam boilers)

- Boiler feed pump in service

- Condensate return temperature (degrees F)

- Water level in condensate tank (normal, low, high)

- Make up water rate (gallons)

FORCED HOT WATER CIRCULATING SYSTEM

- Circulating pumps in service

- Return water temperature (degrees F)

- Water level in expansion tank (normal, high, low)

BOILER WATER TREATMENT

- Level of chemicals in treatment tank

- Treatment pump in service (low, normal)

- Boiler water sample taken

MAINTENANCE OR REPAIR OPERATIONS

- When maintenance action is taken in the boiler room or plant these operations should be recorded in the boiler operator’s logbook as well as documented and recorded in the maintenance log. The operator’s log details what is being done, identifying the item and who is working on it. The maintenance log details the specifics of the equipment and the work being done to fix problem (scope).

3. SUGGESTED MAINTENANCE LOG PROGRAM

Note: Each plant is different; the following is only for example. A responsible Plant Engineer, Chief Engineer, Operations Manager, Maintenance Manager, Director or Facilities Supervisor, etc., should establish a log with at least the minimum below. In most cases more is needed to provide a true representation of the program and its objectives.

The following maintenance items, as appropriate to the specific boiler system, need to be considered for implementation on a regular basis (e.g., daily, weekly, monthly, semiannually, and annually). A checklist of the items should be incorporated into a maintenance log with provisions for checking off the item for the appropriate period.

A separate log sheet is suggested for each period. The log sheets can be filed in a loose-leaf binder, and should be retained as a permanent maintenance record. The log sheets can be used as a handy check-off system when establishing a facility maintenance program. In all cases, the equipment manufacturer’s recommendations should be followed.

DAILY

- Blow down and test low water cutoffs of steam boilers (once per shift for high pressure)

- Blow down gage glasses (steam)

- Blow down make up feeder (low pressure steam)

- Blow down boiler (steam)

- Check boiler control linkage

- Check boiler and system for leaks

- Check burner flame

WEEKLY

- Check compressor(s) lubricating oil level (control and atomizing)

- Check flame signal strength for both pilot and main flame, and record readings

- Check flame failure cutoff and timing

- Check pilot and main flame fuel shutoff valve closing

- Check igniter and burner operation

- Check level in chemical treatment tank

MONTHLY

- Check compressor(s) air filter, and clean or replace as required

- Check boiler water treatment test results received from treatment company, adjust treatment as required

- Lubricate motor and equipment bearings

- Test fan and air pressure interlocks

- Check main burner fuel safety shutoff valves for leakage

- Check low fire start interlock

- Check high pressure / temperature interlocks

- Test low water cutoffs (hot water)

- For oil – test pressure and temperature interlocks

- For gas – test high and low gas pressure interlocks

- Manually lift safety/safety relief valves and check operation

SEMI-ANNUALLY

- Inspect burner components

- Check flame failure system components

- Check piping and wiring of all interlocks and shutoff valves

- Recalibrate all indicating and recording gages and instruments

- Perform a slow drain test for low water cutoffs (steam)

- Check combustion control system

- For oil – check atomizers and strainers

- Test boiler safety/safety relief valves in accordance with ASME Boiler and Pressure Vessel Code, CSD-1 and applicable ASME Code Sections VI and VII, and the National Board Inspection Code (NBIC-ANSI-NB 23, NFPA 85).

- When necessary replace safety relief valves with the proper rating and capacity in accordance with manufacturer’s specifications.

ANNUALLY

- Perform the SEMI-ANNUAL maintenance procedures

- Check all equipment coils and diaphragms

- Perform a pilot turndown test

- Recondition or replace low water cutoff

- For gas – check drip leg and gas strainer

- Clean boiler firesides

- Drain boiler, open manholes and hand holes, and clean watersides

- Have boiler inspected by a commissioned inspector

- Clean burner and fans

- Replace gaskets

- Leak-test all fuel valves

- Test operation of all controls and safety devices

- Have fuel-burning system adjusted using combustion test instruments

AFTER EACH PERIOD

- Make a record of all maintenance and parts replacements in the maintenance log.

MAINTENANCE AND SERVICE

- It is suggested that the equipment owner ensure that the service and/or maintenance company meets the adopted codes and standards to ensure compliance. In addition, the service or repair should be capable of complying and providing service to a minimum of the following:

- Document for the owner specific testing made on controls and safety devices in accordance to the manufacturer’s specifications and the adopted codes and standards and;

- Have necessary testing and calibration equipment to perform “proof testing” of the controls and safety devices and;

- Comply with ASME CSD-1, 2001 edition; reference only the section on testing, logbooks and operational checks and;

- Maintain copies of and follow the ASME Code Sections VI and VII, 2001 or current edition, Rules for the Care and Operation of Heating Boilers, Recommended Guidelines for the Care of Power Boilers and;

- Must be able to provide service in accordance to the recommendations and specifications of the original equipment manufacturer (OEM) or equivalent. When necessary, obsolete equipment should be replaced to ensure safety and reliability.

- Replacement controls and safety devices must be purchased from companies that are certified and recognized by national testing standards (UL, FM Approved).

4. LOGBOOK EXAMPLE

THIS IS AN EXAMPLE OF THE INSIDE FRONT COVER OF A HARDBOUND LOGBOOK

No person shall deface, damage, destroy or, without permission of the user, remove this logbook from the plant. The Chief Engineer shall ensure that this logbook is kept accessible in the plant for at least three years after the last entry herein and shall produce this logbook for examination upon the request of an inspector.

Signatures of Boiler Room Staff

This logbook was Opened on MM/DD/YYYY

By:_____________________________________________

Name (Printed) Signature Position Date

4.1 BOILER OPERATOR’S LOGBOOK EXAMPLE OF OPERATOR’S DAILY LOG ENTRIES

Sign In: Senior Mann Trainee: Carl Knew

7:00am – Took over watch and made a round of boiler room; noted a strong smell of gas upon entering the north entrance; all operational conditions appear to be satisfactory. Blowdown performed on Boiler

# 1 & #2. Took fuel oil tank sounding; noted same on fuel and readings sheet. Gas leak could not be detected upon checking piping; smell of gas not too strong as noted in boiler room upon entering; noted possible leak to supervisor at 7:15 a.m.

Carl Knew in plant for hands-on training at 7 am.

8:15am – Responding to a call from room “XXX” which has no heat. Reported same to maintenance (or if person maintenance they would write – found “XXX” facility or room without heat; isolated system and repaired.) or unable to repair at present, completed work order or request form etc. Returned to boiler room at 8:45 am and made operational checks. All conditions satisfactory, no smell of gas at present. Boiler is running on load demand. Low water fuel cutoff test performed by opening blow- off valve on water column; Test okay, burner tripped, reset and post-purged and restarted as required. Observed purge and light off, OK.

9:15am – Out of boiler room making a round of premises or facility; comfort control and heating system check OK, note that setback timer is off by 90 minutes. Is this correct? Noted same to supervisor by radio (or by telephone, whichever is applicable).

9:30am – Responding to call of water leak in hallway from ceiling. Found packing gland loose on a steam valve; screwed down on gland and leak stopped. Completed a work request to have valve packed or replaced.

10:30am – Boiler alarm signal received, returned to boiler room. Found low water trip alarm indication. According to burner control system or “Fire-eye or Honeywell LCD display indicated LOCKOUT trip at 10:20 am”. Verified water level normal, manually reset, boiler restarted OK. Steam pressure at 2 psi now. Observed purge to main flame start. Verified operation of condensate system and MU (Make-Up) water. Unable to determine reason for the low water at present. All conditions appear to be normal. Reset control and restarted as instructed by supervisor.

11:45am – Round made in boiler plant, completed inspection checklist – conditions appear to be normal. 12:00pm – Break for lunch.

1:05pm – Boiler put on stand-by1. Outside temperature is above normal at present time. Notified supervisor

(or whoever would have to be advised in this case).

2:45pm – Made a round of boiler room – no unusual conditions detected. 3:00pm – Signed out – relieved by Charlie Boy.

Signature: Senior Mann Trainee: Carl Knew Trainee Hours: 5 hours by SM

1 Management procedures may vary, and this operation usually depends upon the season annal authority.

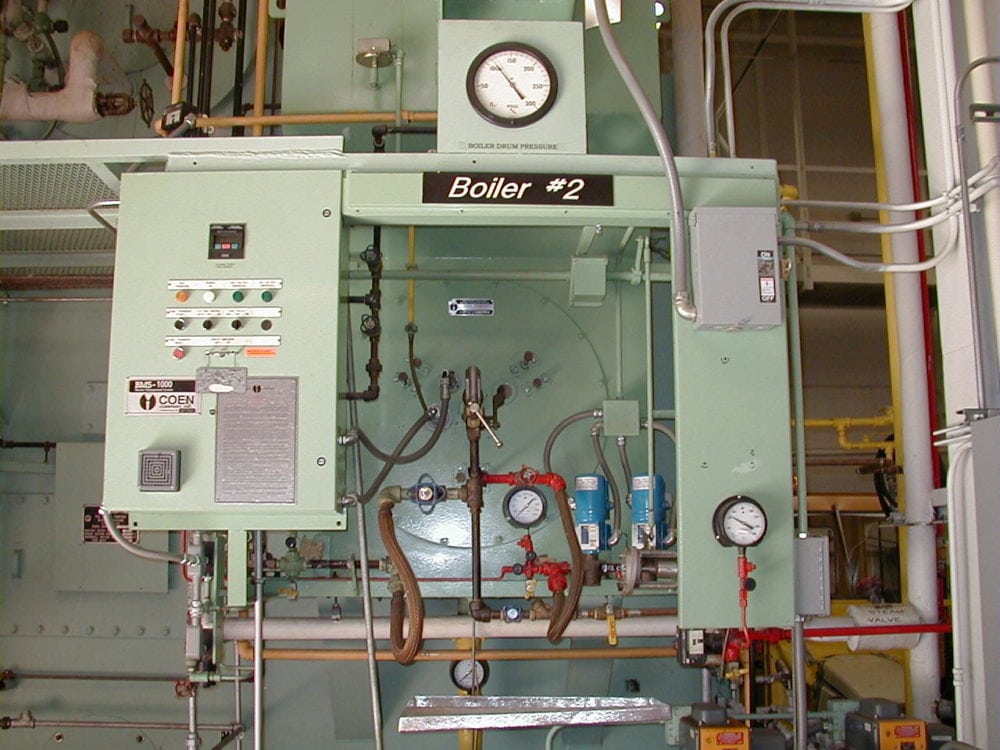

Show a picture of an incorrect installation and a correct installation.

5. BEST PRACTICE

- Establish plant standards for safety valve installation and selections per the Steam Best Practices.

- Add all safety valves to a database.

- Review all safety valves periodically, depending on plant standards; insurance company recommendations; and federal, state, or local government requirements.